Baddi: How NDA 2.0 can fix Himachal Pradesh's industrial corridor of uncertainty

Industries across the region have pinned their hopes on the upcoming Budget on July 5, hoping the government will announce a manufacturing boost

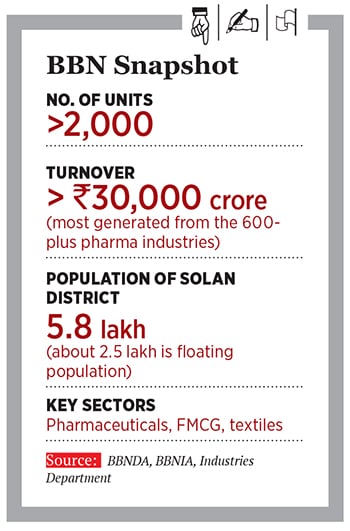

The Baddi-Barotiwala-Nalagarh (BBN) region has over 2,000 factories

The Baddi-Barotiwala-Nalagarh (BBN) region has over 2,000 factories

Image: Rajendra Mehra for Forbes India[br]Shailesh Aggarwal recalls a rather “embarrassing” meeting with Minister of Road Transport and Highways Nitin Gadkari this April. It was a month before the general elections, and Aggarwal was in Gadkari’s Delhi office to discuss a poll issue in his home-state Himachal Pradesh.

Representing an association of businesspeople in the Baddi-Barotiwala-Nalagarh (BBN) region—the state’s largest industrial township, located in the Solan district—Aggarwal requested Gadkari to fast-track the four-laning of the Pinjore-Nalagarh stretch of the National Highway 21A. The minister, in 2017, had laid the foundation stone for the project that was meant to improve connectivity to and from the BBN region, but it has been in limbo since.

What has made matters worse is the fact that the industrial belt—it has over 2,000 factories, including some of India’s biggest pharmaceutical and consumer companies—does not have a fully-functioning railway network. The rail project connecting Baddi with Pinjore, approved by the central government in 2017, has come to a standstill.

Gadkari, however, simply blamed the Himachal Pradesh government for the delays. The National Highway Authority of India officials were not agreeing to the high compensation rate for land acquisition that the HP government (reportedly around ₹9 crore per hectare) has fixed for the four-laning project. “He [Gadkari] asked me to first check what my state government is doing about this,” Aggarwal recalls. The state government, on the other hand, claims they are helpless as the Centre is not being more proactive with the project.

Aggarwal says this lack of coordination, despite a Bharatiya Janata Party (BJP) government both in the state and Centre, will only further harm industries. “They are just passing the buck without finding solutions. Ultimately, it is the industry and local people who suffer. There is a big gap in infrastructure around industries and basic connectivity is becoming a nightmare.” As president of the Baddi Barotiwala Nalagarh Industries Association (BBNIA), Aggarwal is concerned about how companies are either contemplating moving out of the BBN region, or had already left. “This blame game has to end. Both entities must coordinate better.”

The MSME (micro small and medium enterprises) sector, which saw a slump due to demonetisation and the Goods and Service Tax (GST), did not receive too many incentives in the interim Budget this February. Piyush Goyal—who was the finance minister then—had simply reiterated the November 2018 announcement by Prime Minister Narendra Modi, that loans up to ₹1 crore will be sanctioned in 59 minutes to GST-approved SME units, with 2 percent interest rebate on fresh or incremental loans of ₹1 crore.

Harish Agarwal, chairman, Confederation of Indian Industry (CII) Himachal Pradesh State Council, says the Budget has to come out in full support of MSMEs. “Banks have to be liberal in funding manufacturing activities. Single-window clearances are not implemented properly across states.”

According to the Economic Survey 2017-18, of the total outstanding credit of ₹26,04,100 crore disbursed by banks as on November 2017, only 17.4 percent was for MSMEs, while 82.6 percent was for large enterprises. The interim budget did not address these concerns, and made no changes in indirect taxation.

Manufacturing contributes between 16 and 19 percent of India’s total GDP, and has stagnated for almost three decades now. Through the ambitious Make in India initiative, Modi had promised to increase the share of manufacturing to 25 percent of GDP by 2025, and creating 10 crore jobs by 2022.

Agarwal explains that in the long-term, going beyond financial incentives, the government needs to develop infrastructure around manufacturing hubs. “The concept of ease of doing business is often restricted to incentives, permissions and clearances, but what after that? A lot depends on increasing cooperation between businesses and officials, addressing labour issues, roads and basic connectivity.”

A Half-hearted push?

Certain challenges, like the state government"s long-winded land-acquisition procedures under Section 118 of the HP Tenancy & Land Reforms Act, 1972, and transport unions demanding steep freight charges, are unique to the BBN region. But, larger policy and implementation issues like lack of business and social infrastructure development are to be found in other industrial belts too, specifically in hill states.

The Make in India website lists the 35 km-long BBN industrial corridor as one of the four ‘Maker Towns’ that is “putting India on the map”, the others being older centres in Rajkot (Gujarat), Tirupur (Tamil Nadu) and Chakan (Maharashtra).

The BBN hub, on the foothills of the Himalayas, started by scripting what seemed like a success story: Traditionally known for producing apples, it saw an industrial explosion when former Prime Minister Atal Bihari Vajpayee, in 2003, granted industries a 10-year exemption from paying excise duty, and a five-year exemption from income tax.

Earlier, in the ’90s, the Vajpayee-led National Democratic Alliance (NDA) government had also introduced reforms in India’s telecom policy, apart from constituting the National Task Force on Information Technology and Software Development, which made IT companies the centre of job creation, investments and exports.

In 2003, along with the BBN area, tax holidays were granted in Uttarakhand, Jammu and Kashmir and Northeast India. The idea was to encourage industrial investments in hilly states, where it is difficult to set up and run factories because of the terrain. Moreover, these states are neither hubs for raw material, nor finished goods, which make them more dependent on transport and connectivity infrastructure. Given that governments have not developed infrastructure at the same pace as attracting investments, it poses a challenge for long-term manufacturing activities.

The tax exemption period for BBN, from 2003 to 2013, was curtailed by the United Progressive Alliance (UPA) government in 2010. While the tax package has already ended for most companies, the sunset period for those set up in 2010 extends till 2020. The tax holidays in the Northeast extend till 2027, which continues to attract steady investments while in Uttarakhand, like in HP, the tax holidays have lapsed. Industries in Uttarakhand face greater scrutiny for environmental violations, given that the state has about 61 factories in the main stem of the Ganga and a forest cover of over 38,000 sq km that constitutes 71 percent of its total geographical area.

GST, however, turned direct tax exemptions into a refund (under the central government’s Scheme of Budgetary Support) for those industries whose sunset period extended till 2020. “Companies are facing delays in getting GST refunds,” says Aggarwal, who also says that “cartelisation of transport” by unions has increased freight charges. “With over 10,000 trucks, ours is among the largest transport unions in Asia, but their prices are 40 percent higher.”

Despite these challenges, the BBN belt contributes more than 30 percent of HP’s total revenues. About half the units in the area belong to pharmaceutics and ancillary industries, making the region the unofficial pharma capital of India. Companies include Cipla, Unichem, Dr Reddy’s, Abbott and Glenmark they did not respond to Forbes India’s request for comment. FMCG and textile companies in the area include Dabur, Colgate-Palmolive, L’Oreal and Vardhman Textiles.

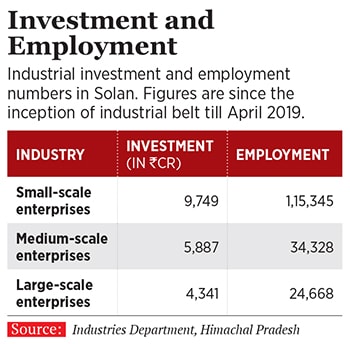

According to the state industries department, the Solan district has seen industrial investments worth ₹19,976 crore between 2003 and April 2019. Local industrial bodies have estimated that the area’s total annual turnover is over ₹40,000 crore.

Making Make in India possible

Industrialists believe that successive governments have failed to capitalise on the momentum given to industries by the Vajpayee government. As per numbers presented in the HP Legislative Assembly, about 118 industrial units have shut down in the last three years, and over 9 lakh people are facing unemployment. Agarwal claims that HP’s unemployment numbers are among the highest in North India. Rajesh Bansal, whose company BRD Medilabs has been operating in BBN for 25 years and has manufactured medicines for Cipla and Wockhardt, believes that the very qualities that attracted industries to Baddi are now fading. BBN, he says, enjoyed uninterrupted power supply, good climate and availability of land. “Today, there is a space crunch and haphazard development,” he says, adding that heavy truck traffic in the absence of good roads results in congestion and accidents. The local container depot is also underutilised containers loaded in BBN are shipped to Ludhiana, which is about 110 km away. “So transport, freight expenses, logistics and overheads remain high,” he says.

Rajesh Bansal, whose company BRD Medilabs has been operating in BBN for 25 years and has manufactured medicines for Cipla and Wockhardt, believes that the very qualities that attracted industries to Baddi are now fading. BBN, he says, enjoyed uninterrupted power supply, good climate and availability of land. “Today, there is a space crunch and haphazard development,” he says, adding that heavy truck traffic in the absence of good roads results in congestion and accidents. The local container depot is also underutilised containers loaded in BBN are shipped to Ludhiana, which is about 110 km away. “So transport, freight expenses, logistics and overheads remain high,” he says.

Bansal’s expectation from the Budget is simple: Make the industry self-sufficient by fast-tracking and executing projects that continue to remain only on paper. For instance, Centre-aided projects like a pharma testing lab and the Baddi Trade Centre (with sanctioned budgets of ₹8 crore and ₹14 crore respectively) have failed to fructify.

“There is no development in the Central government’s ambitious plan to set up a drug park in Baddi, to boost bulk production, despite the project being announced three years ago,” he says. The park was being created to reduce the dependence of Indian pharma companies on Chinese firms for active pharmaceutical ingredients (APIs), or raw materials. Over 75 percent of APIs are sourced from China.

Another factor negatively impacting BBN, says Bansal, is the lack of education, health care and other common facilities. He claims that over 90 percent of entrepreneurs in Baddi have moved home to Chandigarh and Panchkula—about 50 km away—an option he too will soon pick. “Each of us industrialists has to spend about three hours commuting. This adds to traffic problems, but we are helpless since Baddi has no social infrastructure,” he says.

The government is hoping that the Himachal Pradesh Industrial Investment Policy 2019, approved by a Cabinet Committee chaired by Chief Minister Jai Ram Thakur on June 1, will help the state script a turnaround. Sanjay Kanwar, deputy director, industries department, says the new policy—to be enforced by the end of June—will simplify land acquisition procedures, create physical and social infrastructure, improve access to credit and the market, digitise government processes, encourage self-certification and boost employment.

“There will be incentives on land allotment rates and power rebates. We will also streamline procurement of essentiality certificates to set up businesses, and help with environmental clearances,” he says, claiming to have signed MoUs worth ₹1,000 crore with industries in May. Like neighbouring Uttarakhand and the Northeast, Kanwar says HP will also be aggressive in attracting more investors.

People employed in industries have only one expectation from the Budget and their government: Job security and financial stability. Devbrat Mani, 29, a quality expert at Classy Kontainers, which designs packaging solutions, is facing a layoff as the Mumbai-headquartered company wants to shut down their Baddi facility and retain the one in Visakhapatnam. “I have been in Baddi for 10 years and have shifted two jobs because of companies scaling down operations here. Industries only look at profitability, but who will tell them or the government that while chasing numbers and targets, they should also spare a thought for labourers and their livelihood?” he says.

First Published: Jul 01, 2019, 12:07

Subscribe Now