Dark stores explained: The tech behind 10-min delivery

Cramped dark stores are tech-enabled, micro warehouses where the countdown begins once an order is received, and is processed within minutes

Dark stores are the most critical cog in the wheel for quick commerce companies to run smoothly. From the moment a customer places an order to the time it’s delivered at their doorstep, every step has to function seamlessly, and very quickly within these high-efficiency, tech-enabled spaces. Unlike traditional retail outlets, dark stores are not open to walk-in customers; they exist solely to sort, pack, and dispatch online orders with speed and precision.

At their core, dark stores are designed to handle a growing number of orders by maximising operational efficiency, inventory density, and proximity to demand, which together generate higher revenue per square foot. They operate with lower overheads, higher inventory density, and greater flexibility. Located in smaller, cost-effective spaces compared to brick-and-mortar retail shops, they bring products closer to demand hotspots. This proximity is critical to fulfilling the promise of 10-minute deliveries.

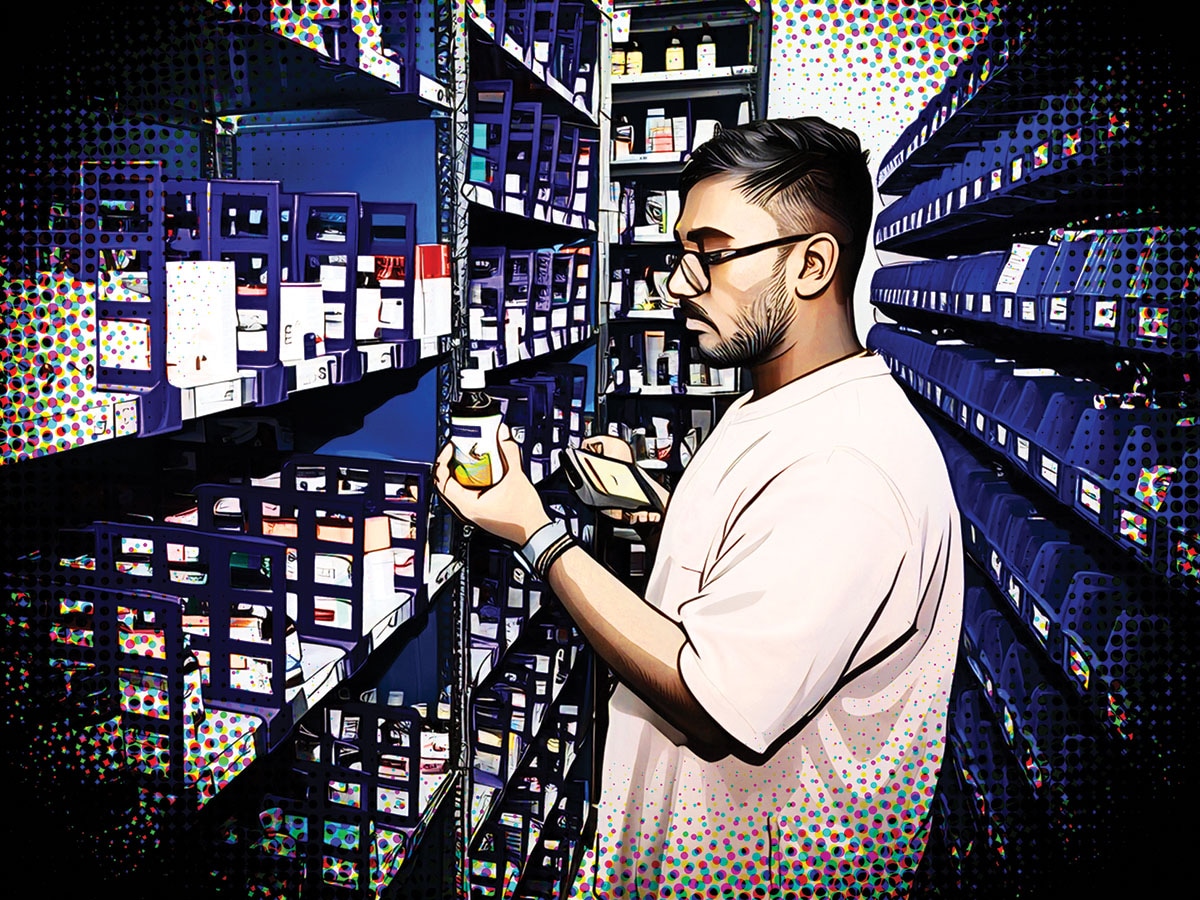

The model is powered by advanced warehouse management systems and AI-led inventory planning. These systems track rate of sale, optimise product placement, and ensure real-time visibility across supply chains. Every product is tagged, scanned, and tracked; fast-moving items are placed closest to dispatch zones, while slower-moving goods are kept deeper inside the store.

Quick commerce relies on its ability to predict hyperlocal demand, and tailoring inventory to specific PIN codes. A product trending in one neighbourhood may not move in another. This requires agile supply chain planning, fast replenishment cycles, and tight coordination, especially during demand spikes such as festivals or cricket matches.

Despite the consumer love for instant delivery, profitability remains a challenge. The economics of dark stores hinge on high order volumes, operational discipline, and customer retention. While some are turning profitable, others struggle due to intense competition and the scale of investment required.

As the sector matures, the focus is shifting from speed to building resilient and scalable ecosystems. Success will depend on balancing innovation with cost control, expanding into broader retail categories, and earning long-term consumer trust.

When a customer places an order through the app, it immediately reflects in the store’s Warehouse Management System (WMS). This system is designed to manage everything from inventory to picking and packing. The order appears on the packer’s handheld device, showing the order ID, items, and their respective bin locations. This ensures visibility and traceability from the very beginning.

The system assigns the order to a packer, who must be online and ready to accept tasks. The device displays all relevant details, including the EAN (European Article Number) for each item, which must be scanned to confirm accuracy. The system also tracks productivity using a metric called IPP (Items Per Pick), which calculates how many items a packer picks per unit of time.

Each bag is scanned and tagged to the specific order ID, creating a digital link between the physical package and the order.

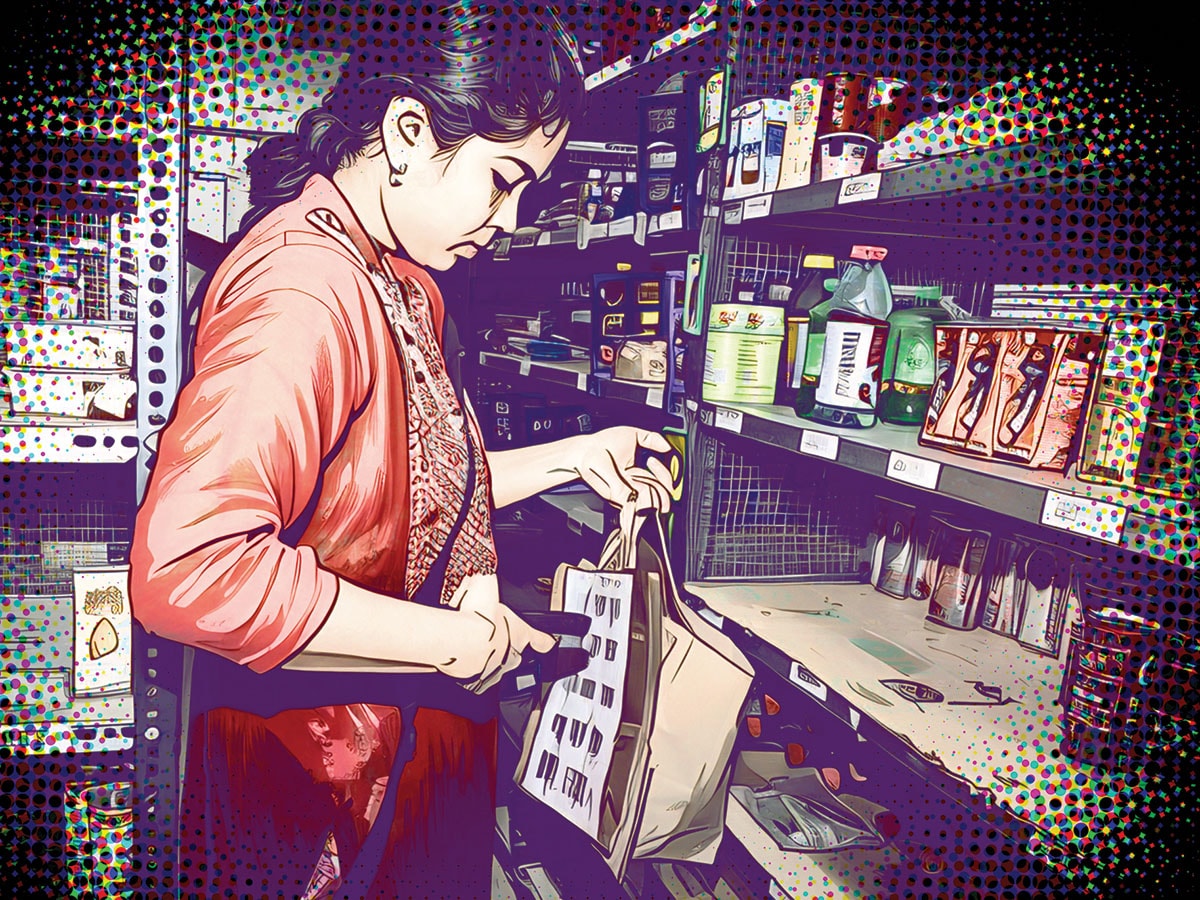

The dark store is divided into multiple zones based on product type and storage requirements: Dry goods, chiller, freezer, meat/milk room, and ambient temperature zones.

Packers follow a sequential picking route optimised to prevent damage (e.g., fragile items like eggs are picked last). Each item is scanned to ensure it matches the order exactly, preventing errors like picking the wrong brand or variant.

During picking, packers perform quality checks to ensure items are not expired, damaged, or substandard. Perishable items like dairy and fresh produce are checked multiple times a day. If an item fails QC, it is removed from the system and either replaced or marked for return. This ensures only fresh and safe products reach the customer.

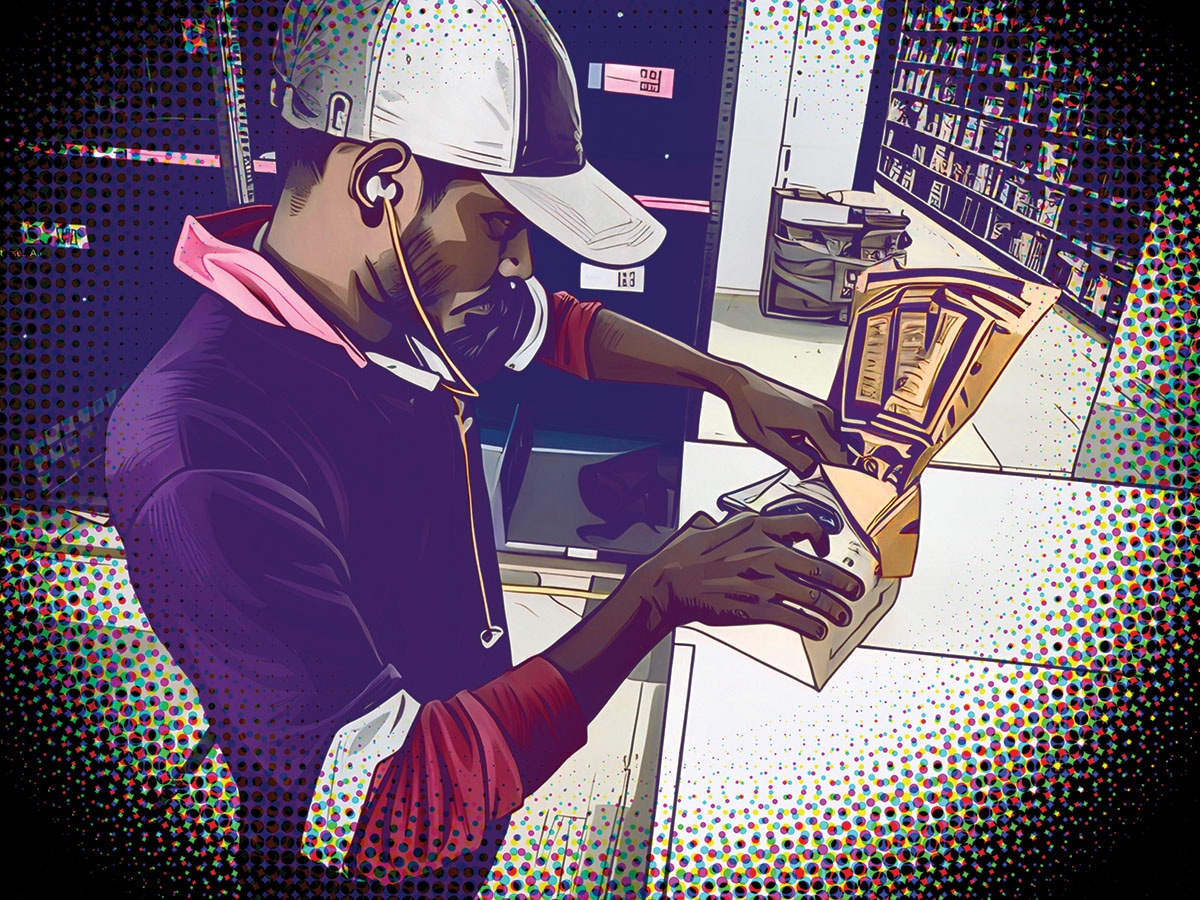

Once all items are packed and put inside the bags, they are placed in colour-coded pigeon holes (e.g., Red 1, Blue 3), which serve as designated pickup points for delivery riders.

Riders arrive at the store and scan the order barcode at the pigeon hole. They do not enter the store; the pickup is contactless and efficient. The app shows them the delivery location, but no personal contact details are shared.

First Published: Oct 09, 2025, 16:27

Subscribe Now