Faster, leaner, smarter: How Zyod is changing garment manufacturing in India

Zyod’s AI-powered software platform streamlines garment manufacturing processes, thus cutting down on design-to-delivery timelines

When most people think about artificial intelligence (AI), they usually think about disappearing jobs and machines replacing people. But at Zyod, AI does what it is meant to: Make work smarter and simpler. By doing so, the Gurugram-based, tech-enabled manufacturing company helps brands and suppliers navigate the complex apparel business from design to delivery.

“Every single part of the apparel business is difficult,” says Ritesh Khandelwal, co-founder of Zyod. “From design to sourcing, production to delivery—nothing is easy. But our job is to take on that difficulty, so our clients don’t have to. And that’s where AI helps us. It’s a tool, not a replacement.”

His co-founder, Ankit Jaipuria, born into a textiles family in Jaipur, agrees: “I saw there was a lot of struggle and hassle. It was never exciting, honestly.” He pursued mechanical engineering at IIT-Delhi and later became a management consultant, learning about supply chains, manufacturing, and operations. The turning point came during the Covid-19 pandemic, when Jaipuria explored an early-stage fashion business started by his college seniors. That experience exposed him to the challenges and inefficiencies of manufacturing in the fashion sector. He and Khandelwal co-founded Zyod in January 2023 with a clear mission: “Making business easy in fashion.”

“With online retail, trends change every month. Consumers are exposed to new trends all the time. To keep up, brands need partners who can match that speed without compromising quality,” says Khandelwal.

In traditional apparel manufacturing, however, cycles were long and sluggish, where brands launched two or three collections a year, and production timelines stretched across months. By the time a trend hit store shelves, it was already halfway out of fashion.

Zyod has two manufacturing units, in Jaipur and Gurugram, and works on contractual arrangements with other apparel factories, based on their expertise. The AI-powered, proprietary software platform that it has built is used in their manufacturing units, as well as those that it partners with.

The platform uses data analytics and reduces the conventional months-long cycle to a 45-day cycle, thus responding to trends faster and reducing inventory. This also ensures that brands can test and iterate on designs much faster. For instance, when new fabric arrives, the system updates all relevant teams—from fabric cutters to production staff—so that the production pipeline can work almost in real time. A standard operating procedure ensures uniformity across factories, while dashboards and software tools allow managers and workers to track every step.

When a brand uploads a design idea or trend reference, Zyod’s system analyses similar patterns and suggests fabrics, trims, and stitching details. It can recommend the most suitable suppliers, factoring in costs, timelines, and quality records. This enables both small D2C companies and large retailers to operate with the same efficiency. “Someone might say, ‘Make it two inches longer’ or ‘I want this in green and white stripes,’” Jaipuria says. To manage this variability, Zyod’s platform standardises processes while allowing flexibility.

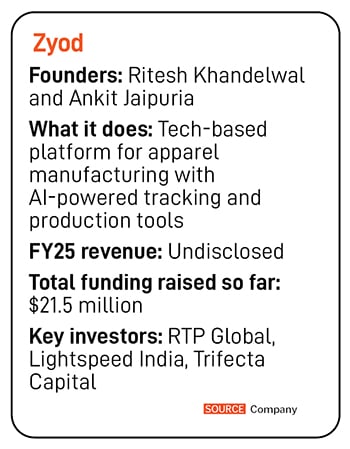

Although the company declined to disclose its revenue figures, according to Tracxn, a startup data platform, Zyod earned a revenue of ₹31.2 crore as of March 2024; it has raised a total funding of $21.5 million over three rounds, since March 2023. Tracxn adds that Zyod has raised funds from 11 institutional investors, including RTP Global, Lightspeed India and Trifecta Capital.

During its last funding round in June 2024, Nishit Garg, partner at RTP Global said, “Zyod is transforming the way fashion brands and retailers source and manufacture products. By lowering minimum order quantities and slashing lead times, they’re making fashion more agile and accessible.”

Also Read: Led by grandma’s clean recipes, Sweet Karam Coffee is riding the D2C wave

India is one the world’s largest garment manufacturers, ranking fifth after China, Bangladesh, Vietnam, and Turkey. The sector contributes about 2.3 percent to GDP and employs over 45 million people directly, according to India Brand Equity Foundation (IBEF). In FY24, the country exported textiles and apparel worth $35.6 billion; this number is projected to reach $387 billion by 2028. Its main export markets include the US, UAE, UK and Germany. Backed by schemes like the PLI and PM MITRA parks, the government is looking to boost Indian garment exports to $100 billion by 2030.

Zyod has scaled rapidly and, along with its contractual manufacturing partners, supplies garments to brands in more than 40 countries, with offices in Porto, Madrid, London, Tokyo, and Sydney. The company is also investing in fabric innovation. Its Surat research and development (R&D) centre develops new weaves, processes, and sustainable fibres.

“China accounts for 48 percent of global apparel manufacturing, Bangladesh 17 percent, and India only 3 to 4 percent,” Jaipuria notes. “We have the capability and infrastructure to change that. Our mission is to bring India to the forefront of apparel manufacturing over the next five to 10 years.”

Expansion plans focus on deepening relationships in key markets, including Europe, Australia, and Japan, and diversifying product categories. By mapping India’s regional manufacturing capabilities Zyod leverages local expertise to meet global standards.

First Published: Oct 29, 2025, 12:42

Subscribe Now