- Home

- Multimedia

- Photo Gallery

- Explained: The unbelievably complex process of making semiconductor chips

Explained: The unbelievably complex process of making semiconductor chips

Image by : Shutterstock

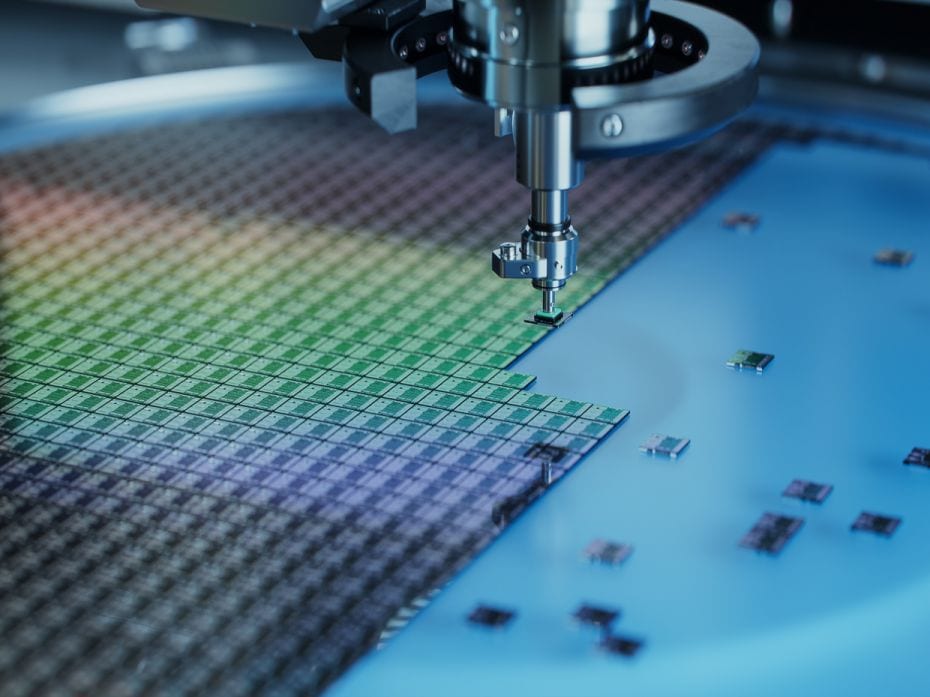

Automated robots transport wafers at an advanced production fab. Semiconductor technologies are so advanced that it's impossible to catch up without pumping in vast sums of money. Building a foundry business takes time—a single leading-edge fab can cost $10-15 billion and take more than four years to finish. Making chips is so complex and specialised that even diversifying the manufacturing location will make it more difficult to maintain quality. The transistor in a 3-nanometer (nm) node is just 1/20,000th the width of a human hair. The key component may only be silicon, but the magic happens in processing and altering it.

Image by : Lam Yik Fei/Bloomberg via Getty Images

Workers gather for a ceremony that marks the beginning of bulk production of advanced 3-nanometer chips at a Taiwan Semiconductor Manufacturing Co. (TSMC) facility in Tainan, Taiwan, December 29, 2022. It took decades for Taiwan to emerge as a semiconductor giant, which began with the transfer of technology from the US in the 1970s to the setting up of TSMC in 1987. The world's biggest contract chip manufacturer today, TSMC's clients include Apple, Intel, Qualcomm, AMD and Nvidia. The $550 billion firm controls more than half the global market for made-to-order chips and has an even tighter stranglehold on the most advanced processors, with more than 90% of the market share by some estimates. Global chip sales were $574 billion as of 2022.

Image by : Eason Lam / Reuters

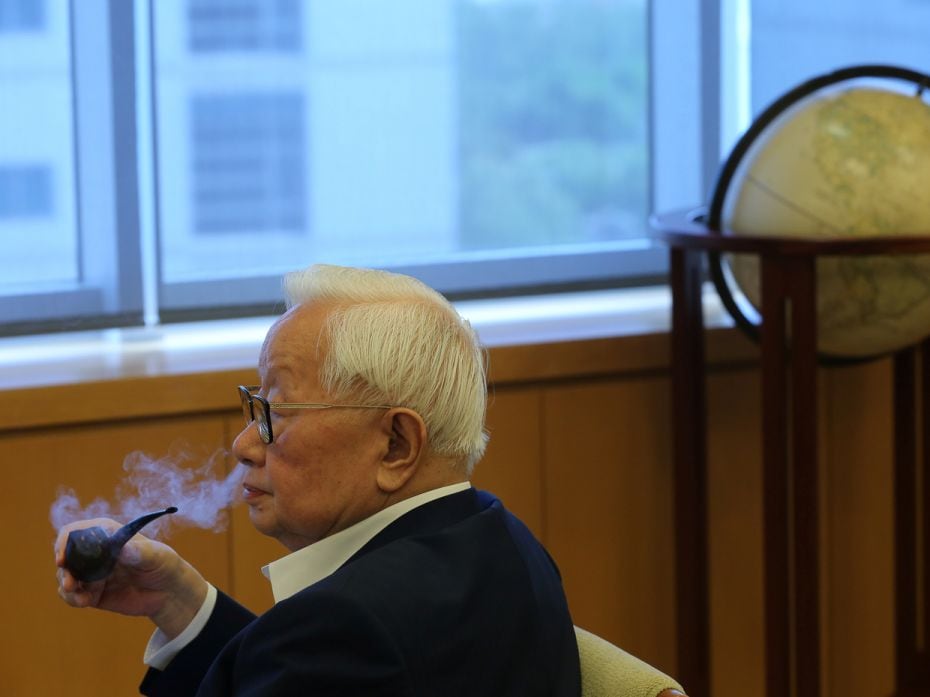

A file photo of TSMC chairman Morris Chang in Hsinchu, Taiwan, October 5, 2017. Chinese-born engineer Morris Chang, who founded TSMC in 1987, studied at Harvard, Stanford and MIT and worked at Texas Instruments for 25 years. Among his many achievements, Chang pioneered the tactic of initially pricing chips at a loss, expecting that gaining an early market share would increase sales.

Image by : Shutterstock

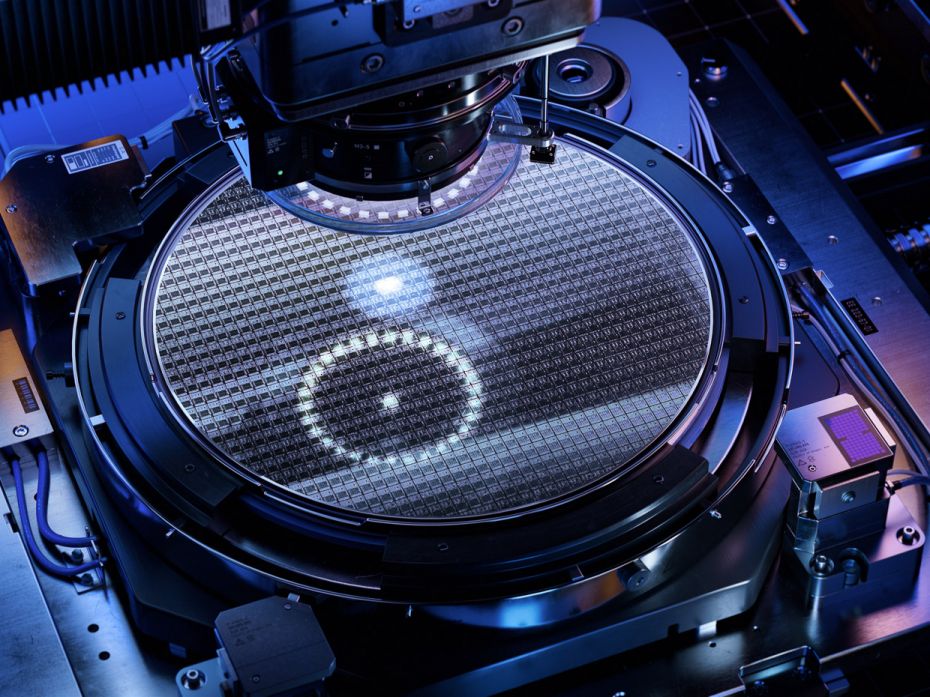

Creating a chip takes hundreds of steps, each with many variables, leading to less than a quarter of the final output being usable. After six to eight weeks of painstaking etching and testing, each wafer can be carved into individual chips for dispatch. To carve these, Taiwan-based TSMC relies on the extreme ultraviolet lithography machines made by just one Dutch firm ASML. Each of these machines costs around $200 million a set.

Image by : Jasper Juinen/Bloomberg via Getty Images

A file photo of employees working on a lithography machine at the ASML Holding NV factory in Veldhoven, Netherlands. ASML, a Dutch company, has a complete hold over the global semiconductor industry, being the only one in the world that owns the technology and makes the machinery to cut and slice thin chips out of silicon wafers physically. ASML is already working on a new generation of lithography machine called high-NA-EUV, which will allow chipmakers to make 2nm processors and mark a major milestone in chip production.

Image by : VCG via Getty Images

Employees work on Apple iPhone production at a Foxconn factory on September 4, 2021, in Zhongmu County, Henan, China. TSMC's recent success has been linked to one client's trust in particular: Apple. For the first six generations of iPhones, Apple had outsourced the manufacturing of its chips to the South Korea-based Samsung. Later, Samsung launched its own competing Galaxy smartphones, causing Apple to file a lawsuit over IP theft in 2011, which ended with Apple winning $539 million in a settlement. That dispute was a boon to TSMC as Apple withdrew its supply chains from Samsung and lay clear of partnerships that favour a potential rival. Taiwan-based TSMC was a dedicated foundry business with no rivalling interests, and Apple remains their biggest client to date.

Image by : SSPL/Getty Images

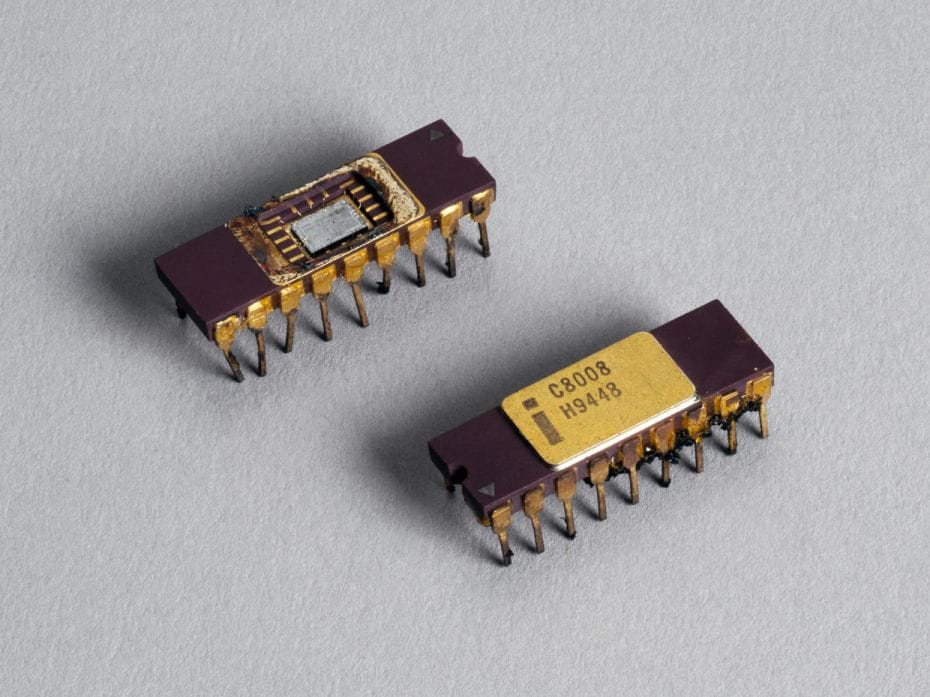

A file photo of the 8080 microprocessor, the first microprocessor powerful enough to build a computer around, introduced by Intel in 1974. Pioneers like Intel designed and built chips in-house at the start of the modern computing industry. By the 1980s, American firms, struggling against Japanese competitors, began outsourcing the fabricating sides of their businesses and concentrated on the more profitable design aspect of the chip. The US has recently turned to global silicon trade for a geostrategic reason. A tech cold war with China began in early 2021 when semiconductor chip shortage and delayed delivery times set off alarms about its utter dependence on China.

Image by : Sam Yeh / AFP

An aerial view of Keelung Harbour, Taiwan, on August 4, 2022, as China held military exercises encircling Taiwan. Caught in the tug-of-war between the US and China, TSMC's success is a walk on the razor's edge. So it is for Taiwan, the island TSMC sits on. The Pentagon is pressuring the US government to invest more in advanced chipmaking locally so that its missiles and fighter jets are not dependent on Taiwan, a self-ruling island that China believes it owns and threatens to invade. This presents a quandary to Taiwan as American firms account for 65 percent of all TSMC sales while China, by virtue of its role as the world's factory, imported around $415 billion worth of chips in 2022 alone.

Image by : Caitlin O'Hara/Bloomberg via Getty Images

A "First Tool-In" ceremony at the TSMC facility under construction in Phoenix, Arizona, US, on December 6, 2022. Despite its dominance of chip design, America is racing to build chipmaking fabs onshore. Intel is revamping its foundry business, building two new fabs in Arizona and a pair of fabs at its Ohio megasite. Last year, TSMC unveiled its US plans, adding a second Arizona fab and investing billions to start production in 2026. In Oct 2022, Micron announced its plans to spend $20 billion to build the largest ever US semiconductor factory, a memory chip fabrication plant in New York's Onondaga County, the size of 40 football fields and create about 50,000 jobs.

Image by : Shutterstock

China, meanwhile, has been casting billions at the semiconductor problem with limited success. Its largest chipmaker SMIC cut off from advanced chip tech due to US sanctions, trails years behind Taiwanese companies in the best chip it can produce. US export controls on Chinese semiconductors have entirely ruined the chip industry, sparking mass bankruptcy in which thousands of companies shut down their business. Then there is Wuhan Hongxin Semiconductor Manufacturing Co., which turned out to be a $20 billion scam perpetrated by tricksters without industry experience.

Image by : Shutterstock

US company Micron Tech's decision to invest $285 million in India is a significant boost for India's semiconductor industry, even if it only intends to set up a chip assembly testing and packaging unit for chips produced in other countries. The unit will help root the expertise and systems required to facilitate chip manufacturing in the future. India has cost-effective and skilled IT professionals, but chipmaking is a complex finishing task that needs critical skills.