Ventures versus the virus: 7 Indian startups fighting the pandemic

These startups have stuck their necks out, innovated and made the fight against coronavirus a common goal

Kochi-based Jayakrishnan T of Asimov Robotics has created the ‘Karmibot’, which can provide essential services like food and medication to patients inside isolation wardsAt any rate, the widening coronavirus crisis can be characterised as a black swan—an unforeseen event with drastic consequences. True to its nature, it has sent markets reeling, stalled economies and brought life to a halt. India’s startup community, however, is showing no signs of abating.

Kochi-based Jayakrishnan T of Asimov Robotics has created the ‘Karmibot’, which can provide essential services like food and medication to patients inside isolation wardsAt any rate, the widening coronavirus crisis can be characterised as a black swan—an unforeseen event with drastic consequences. True to its nature, it has sent markets reeling, stalled economies and brought life to a halt. India’s startup community, however, is showing no signs of abating.

A Gurugram-based startup’s offering, for example—artificial intelligence-driven monitoring of CCTVs in prisons—appears seemingly unconnected to the crisis. Yet the co-founders found purpose amidst the pandemic. They modified their solution to work on a mobile phone, instead of a CCTV camera taught the software to recognise a patient coughing instead of a truant prisoner. Hospitals with low medical staff are ideal use cases for this kind of contactless monitoring. Similarly, a robotics startup based out of Kerala, repurposed its androids to serve patients in isolation wards. A mobile app allows nurses to map the sequence of beds for the food-and-medicine-tray-carrying bot to follow. There’s also a Mumbai-based maker of sanitary napkins who could have carried on with business as usual given the essential nature of its wares. But when the co-founders learnt that the raw materials used in menstrual hygiene products and surgical masks are similar, they retooled their machines to make the latter.

A selection of seven companies that is taking the battle against coronavirus head-on:

Asimov Robotics: Bots To The Rescue

When Jayakrishnan T first heard about coronavirus, it took him back to the difficulties health care workers had to face during the Nipah virus outbreak, in Kerala in 2018. While Nipah was far more dangerous, containing the spread of coronavirus is not turning out to be easy either. Kochi-based Asimov Robotics, however, has been at the forefront, playing a key role by deploying robots in hospitals. In order to have fewer health workers come in contact with Covid-19 patients, Jayakrishnan thought of creating the ‘Karmi-bot’, which can provide essential services like food and medication to patients inside isolation wards.

In March, Jayakrishnan and his team deployed two robots in nearby offices in Kochi, for about 10 days to spread awareness about the disease and the precautions that could be taken. “The robot would play videos created by the World Health Organization [WHO]… during lunch breaks, it would interact with humans and answer any questions that they had about the pandemic, using data and information provided by WHO,” says Jayakrishnan.

Currently the Karmi-bot—driven entirely by artificial intelligence and machine learning technologies—has been equipped with “a tray that can carry both food and medicines, a detachable UV-ray disinfectant box [to disinfect patients’ used items] and an automatic disinfectant sprayer for cleaning hands after eating food,” he says. The bot can be placed near the nursing station, where food and medicines for up to five beds (about 25 kg) can be loaded. Using a mobile phone application, nurses can select the sequence of beds, thus mapping the route for the bot to travel.

While serving food, the bot is equipped to prompt patients to clean hands using the disinfectant. It also allows patients to have human interactions with the caregivers through the screen on the bot, via video calls. “The UV rays used to disinfect the detachable box are only turned on when the bot is on the move. The minute it stops or the box is opened, the light turns off automatically since they [UV rays] can be harmful for the human skin,” says Jayakrishnan.

The team says in case of an issue, 85 to 90 percent of the problems with the bot can be fixed remotely, unless it is a hardware problem.

Recently, the first Karmi-bot was deployed at the Cochin Medical College. Asimov Robotics has been getting a number of inquiries from various state and central governments across the world for the robot. In order to scale up, the team is in talks with some manufacturing facilities, but “the lockdown itself is proving to be a hindrance”, says Jayakrishnan.

â— Naini Thaker

Prashant Warier says the qXR technology can be used to conduct preliminary tests for Covid-19

Prashant Warier says the qXR technology can be used to conduct preliminary tests for Covid-19

Qure.ai: Door-to-door Testsb

Prashant Warier and Pooja Rao set up Qure.ai about two-and-a-half years ago to make quality health care accessible and affordable by using technology. They started with the most common form of medical imagining technique: X-ray.

Qure.ai’s qXR uses artificial intelligence and machine learning (ML) technologies to interpret chest X-rays within seconds. Warier, who is CEO and co-founder, says, “We have a database of 2.5 million chest X-rays that has been used to train our ML algorithms.” Currently, qXR can detect 20 types of abnormalities, and identify and mark out the contours of each. “Several publications have shown that our algorithm is more accurate in interpreting chest X-rays than radiologists,” he adds.

The company first applied this technology for the diagnosis of tuberculosis (TB) and deployed it in about 15 countries. Whether or not a person has lung TB can be confirmed by a Genexpert test, which costs $10 to $30 (₹750 to ₹3,000). However, Qure.ai’s solution can be used as a preliminary test. “Only if the X-ray test turns out to be positive, the patients need to do the Genexpert test. X-rays are cheap anyway,” says Warier.

The Qure.ai team realised that making minor tweaks to the technology can help in detection of Covid-19 patients, since it is also a pulmonary condition. According to the company, the technology could be used first to determine the order of treatment, since there aren’t enough test kits, and second to see how a patient is recovering during the course of the treatment. “A mobile van with an X-ray machine can go door-to-door to test patients. The qXR technology can detect an abnormality within seconds. If a person tests positive, a swab could be collected for the PCR [polymerise chain reaction] test, which is required for Covid-19 diagnosis,” says Warier. With this method, the doctor can better understand the extent to which the lungs have been affected. Consequently, the right combination of drugs can be prescribed. “You can reach a much higher population with the same number of kits as well as remote places that might not have the infrastructure to do the [PCR] testing,” explains Warier.

Qure.ai—a grantee of India Health Fund, an organisation seeded by Tata Trusts to identify and support breakthrough innovations—is in talks with several global organisations and governments to use its technology to ramp up Covid-19 testing. So far, qXR has been deployed in 40 hospitals in South Asia, Europe and North America, and has processed 5,000 suspected Covid-19 cases per week. In India, Warier says, “The challenge is that the Indian Council of Medical Research has not recommended treatment based on X-rays.”

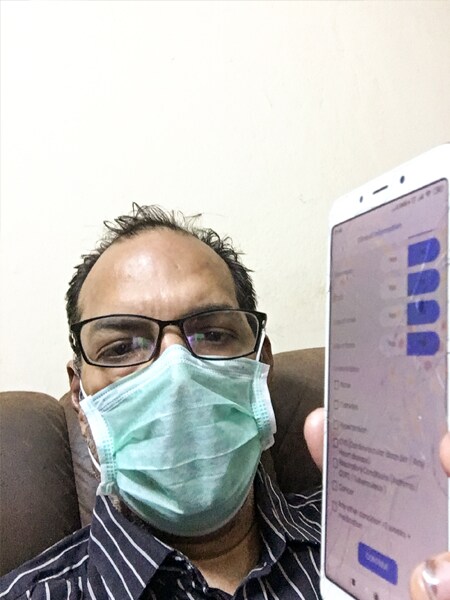

â— Naini Thaker Rahul Pathri of Docturnal is adapting TimBre to detect Covid-19 from the sound of coughsDocturnal: Banking On Data

Rahul Pathri of Docturnal is adapting TimBre to detect Covid-19 from the sound of coughsDocturnal: Banking On Data

Set up in 2016, Hyderabad-based Docturnal launched TimBre—its flagship mobile phone application—to detect patients with lung TB. The sound of an individual’s cough is recorded on a third-party microphone by a medical practitioner and processed in real time to detect if the patient has TB. “We are trying to replicate what a pulmonologist does. Here, the machine learning [ML] model becomes an experienced pulmonologist,” says Rahul Pathri, founder and CIO. With the quality and quantity of data that has been collected over the years, the team is confident of the application’s accuracy. It says the same technology can be used to detect if a person has Covid-19 or not, given that it is also a pulmonary disease. “The pre-beta trial has been completed. We are now in the beta stage and in talks with ICMR to help us with actual patient data for the ML model,” he says.

However, the technology that was created for TB was a business-to-business model, catering to hospitals. Docturnal plans to make the application available to customers, with a ‘do-it-yourself’ (DIY) test—for asymptomatic Covid-19 patients—which could be used as a preliminary test. Apart from this, the company, which is incubated by Social Alpha, has plans to launch a symptom checker as part of its app.

With TimBre, the testing is controlled by a health worker. For the Covid-19 DIY testing tool, however, the Docturnal team is yet to work around some challenges. “Data might be affected by simple changes in parameters. For instance, if the subject is sitting or standing or the distance of the phone from your mouth. A protocol needs to be set for this,” says Pathri, adding that according to the test guidelines, the individual is to cough while wearing a mask.

The team is awaiting Covid-19 patient data from various hospitals and ICMR. Once the data is updated in the ML model, after a short trial with ICMR and the required approvals, Docturnal is confident of taking the platform to the market. The pricing will be around ₹100 per test. “Our focus is not the volume of data, but the type and diversity of the data that we get,” he says.

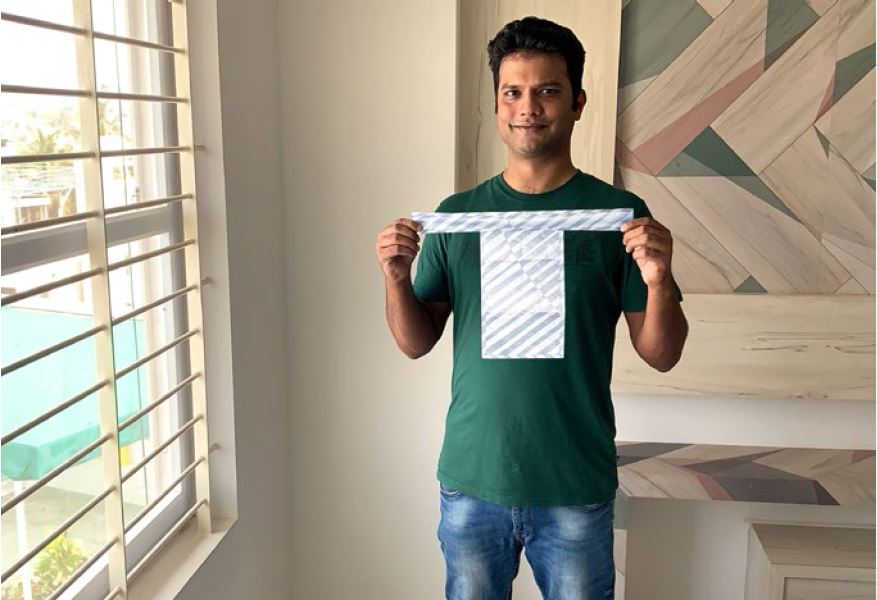

â— Naini Thaker Shashank Mahesh, Innaumation"s co-founder, with a Laryngeal bibInnaumation: Masks With A Difference

Shashank Mahesh, Innaumation"s co-founder, with a Laryngeal bibInnaumation: Masks With A Difference

In 2016, Vishal Rao and Shashank Mahesh set up Innaumation, a medical devices company, to cater to those who lost their voice due to throat cancer. There were devices available in the market that could make them speak, but they were expensive.

The duo designed Aum Voice Prosthesis, a device made of silicon, costing about $1 (₹70 apiece). The innovation was based on the fact that puncturing the food pipe could turn it into voice box.

Incubated by Social Alpha, the company has now created Laryngeal Bibs for its patients. “These patients have a hole in their throat, which means they can’t use regular masks,” explains Rao, co-founder of Innaumation. The company has designed bibs that function like masks to ensure that patients can protect themselves during the coronavirus outbreak. “Cancer patients and elderly people are more prone to coronavirus due to their low immunity. In our case, it’s a double whammy because most of our patients are elderly and have other illnesses too,” says Rao.

The design team thought of an innovative idea of creating the design for the bib, which looks like a scarf. Instead of a regular mask for the throat, creating a bib allows cancer patients to effectively cover their throat, which is their new nose. “One of the main innovation was building a heat moisture exchanger, which can moisturise the lungs. The material used to make the bib is water proof, so even while they are bathing, the throat is protected,” says Rao.

The company is ready with raw materials to expand its production capacity for these bibs. Currently, it is providing bibs to patients free of cost.

Seeing the rise in demand for personal protective equipment (PPE) for health care workers, Rao and his team are looking at ways to manufacture PPEs as well.

“We are talking to experts to see if we can use the same material to manufacture PPEs. We are working to scale this up and will begin manufacturing the equipment since it is the need of the hour,” he says. “This [the lockdown] is a true test for any innovator, thanks to the limited time, financing and manpower.”

â— Naini Thaker Suhani Mohan (right) and Kartik Mehta (behind her) modified their machines to produce 3-ply face masks instead of sanitary napkinsSaral Designs: A New Face

Suhani Mohan (right) and Kartik Mehta (behind her) modified their machines to produce 3-ply face masks instead of sanitary napkinsSaral Designs: A New Face

A few months ago, Suhani Mohan and her co-founder Kartik Mehta were pondering over new product launches in the hygiene space. Saral Designs, their five-year-old Mumbai-based, Acumen-funded startup, not only made low-cost, high quality sanitary napkins but also devised—and sold—the machines that made them, spawning 30 micro entrepreneurs across India.

“Suddenly the Covid-19 crisis came to India,” recalls Mehta. And masks were the need of the hour. Says Mohan, “Surgical masks on Amazon were out of stock and the cost had increased by almost 10 times.” Saral’s customers started reaching out to ask whether their sanitary pad-making machines could be repurposed to create masks.

So the duo, began studying how surgical masks are made and learnt that the non-woven raw materials used in sanitary napkins are similar to those used in masks. Immediately the design team, led by Mehta, got to work. Within days—working remotely amid the lockdown—they made modifications to their machines so that they could churn out 3-ply masks instead of sanitary napkins.

But the lockdown posed problems. “We could not find suppliers who could fabricate the components that we needed to modify our machines,” says Mehta, who serves as CTO.

Undeterred, Mohan, the CEO, started shooting out emails to everyone she knew. One of them was a junior from her alma mater, IIT Bombay, who works at the Mahindra Group. “I wrote to her, saying your factories will have these tools and components that we need… will it be possible for us to use them?” says Mohan. Within four hours, the head of Mahindra Automotive got in touch, extending a lifeline.

The car-making giant fabricated the components Saral needed to modify their machines. Saral tested the components, developed prototypes and, once satisfied, shifted base to Mahindra’s facility in suburban Mumbai for mass production. All this within a week of Mohan’s shot-in-the-dark email. Today, they produce and ship 30,000 masks a day to state governments, via Mahindra’s CSR wing, for distribution to frontline workers. “This has been a dream collaboration,” smiles Mohan.

â— Varsha Meghani Gautham Pasupuleti of Bild, which makes automated versions of manual ventilatorsBiodesign Innovation Labs & AgVa Healthcare: A New Lease Of Life

Gautham Pasupuleti of Bild, which makes automated versions of manual ventilatorsBiodesign Innovation Labs & AgVa Healthcare: A New Lease Of Life

Prior to the Covid-19 outbreak, hospitals across India had all of 40,000 ventilators, according to one manufacturer. Of these, about 20 to 25 percent are dysfunctional, leaving around 30,000 to 32,000 functional ventilators. By pumping oxygen into the lungs of patients, ventilators are critical for those in danger of lung failure, experienced by about a tenth of Covid-19 patients.

At maximum output, Bengaluru-based Biodesign Innovation Labs (Bild) can produce about 400 ventilators in a month. While AgVa Healthcare, a Delhi-based ventilator manufacturer, can make 300. But that’s not going to be enough. So they called in help.

AgVa struck a partnership with Maruti Suzuki India to help with mass production. According to the terms of the agreement, AgVa, which sells ventilators at ₹1.5-2 lakh, compared to imported versions that cost upwards of ₹5 lakh, is responsible for the “technology, performance and related matters” of the ventilators, while the carmaker will reach out to its suppliers to produce the required components as well as “upgrade systems” for the production of higher volumes. The partners plan to produce 4,000 units in April, and 10,000 units by May. “The aim is to hit 20,000 ventilators a month as soon as possible,” says Diwakar Vaish, AgVa’s co-founder and CEO.

Meanwhile, the three-year old, Birac-supported Bild, which makes automated versions of manual ventilators costing ₹50,000 to ₹70,000, had been carrying out clinical trials at various hospitals when the Covid-19 crisis struck. “We suddenly received a surge of orders,” says Gautham Pasupuleti, CEO and managing director. To meet the demand, Bild has tied up with Remidio, a Benguluru-based maker of ophthalmology devices, to make 15,000 ventilators over the next 1 to 2 months. Bild will transfer the technology and expertise to them and ensure all compliances are met, says Pasupuleti. The startup is also in talks with Tata Motors and construction machinery maker JCB India for possible partnerships.

But how easy is it to repurpose factories that make cars or construction machinery to now make ventilators? “Making a ventilator is much easier than making a car,” says Ramesh Singh, professor of mechanical engineering at IIT-Bombay. Ventilators themselves are not complex devices, besides automobile manufacturing in India is of “very high quality and competency. So they can definitely do the ramping up process”.

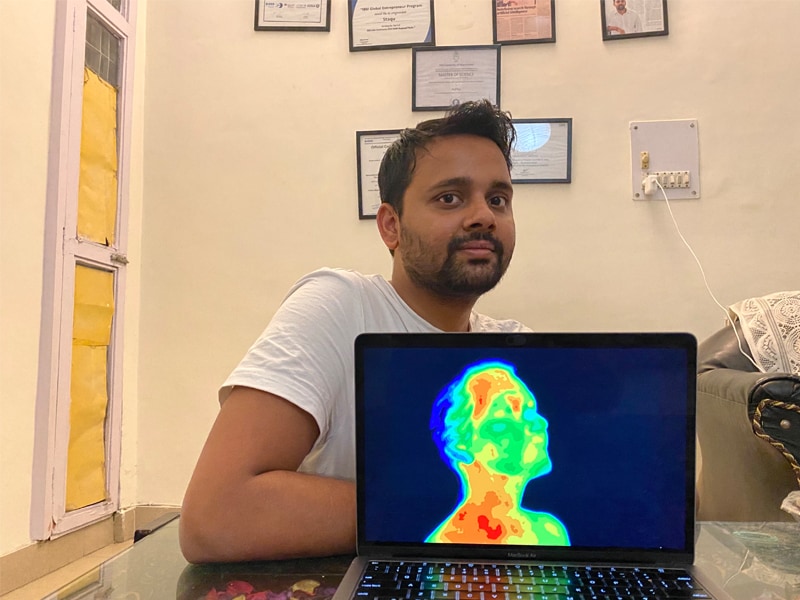

â— Varsha Meghani Atul Rai of Staqu Technologies, which uses thermal cameras to detect body temperaturesStaqu Technologies: Contactless Monitoring

Atul Rai of Staqu Technologies, which uses thermal cameras to detect body temperaturesStaqu Technologies: Contactless Monitoring

In early March when the government issued a guideline that prison inmates and those visiting them must wear masks, Atul Rai immediately got to work. Staqu Technologies, the Gurugram-based startup he co-founded with three others, was already helping the police in Uttar Pradesh monitor CCTVs in prisons, using artificial intelligence (AI). Nicknamed Jarvis, this AI warden monitors 3,000 cameras in 70 prisons across the state. The band of co-founders modified the technology to identify those flouting PPE compliances in prisons because “manually doing so would be impossible”, says Rai. To broad base its use, Staqu further modified the technology to work in places like temporary hospitals where there are no CCTV cameras. “Let’s say this outbreak happens in a huge manner. It’s possible that we might not have enough medical staff to deal with it. In that case, you can use your mobile phone as a streaming device,” says Rai. If a patient coughs, for instance, that will be detected by the adapted Jarvis and relayed to a command centre. A nurse can then tend to the patient. “This allows for contactless monitoring,” says Rai.

Now Staqu has launched an AI-powered thermal camera to detect body temperatures at a range of 5 to 10 m. “A thermal camera basically calculates the temperature of the whole environment where it is placed and gives you the pixel-wise temperature of each of the objects in the scene,” explains Rai.

The technology itself is not new in factories with heavy mechanical operations, it serves as a preventive maintenance tool to detect overheated or overloaded components. Staqu modified the technology to identify the temperature of the human body, particularly uncovered parts like the face or hands, rather than all the objects in the scene.

The Indian Angel Network-funded startup is in the process of finalising contracts with “some airports” looking to leverage this technology to pre-screen travellers for Covid-19, says Rai.

â— Varsha Meghani

First Published: Apr 24, 2020, 11:10

Subscribe Now