Where Boeing Stands Now

Grounding of the 787 raises the questions about the aircraft maker's sourcing strategy

Boeing invested an estimated $25 billion in developing the 787—introducing radical changes in materials and a component-sourcing strategy that was to bring efficiencies for the aircraft-maker and airlines. The grounding of the aircraft raises doubts about these decisions.

1. Critical Decision 1: Lithium-ion

The fact that lithium batteries can overheat and ignite if improperly charged or discharged, is well known. Yet, the batteries are lighter, more efficient than other options like nickel-cadmium (Ni-cad) or lead acid. They allowed the 787’s control systems to be powered by electric motors, compared to less efficient hydraulic systems.

A. Had it been tried before?

In 2011, the US aviation regulator, FAA (Federal Airworthiness Authority) forced business jet maker Cessna to replace Li-ion batteries on its new model CJ4. It was replaced by Ni-cad. However, Cessna plans to qualify Li-ion batteries for use in its new aircraft still being developed. B. So, what went wrong with the 787?

B. So, what went wrong with the 787?

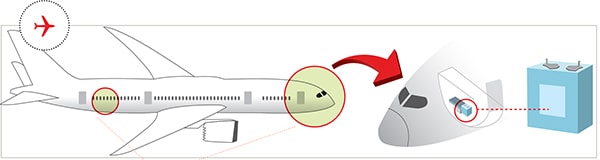

It is not the battery type, but how well it’s monitored that’s key to safe use. On the 787, the battery is integrated into an electronic system designed to prevent overcharging. In the All Nippon Airways fire on January 16, it is still unclear if it was the battery that failed, or the monitoring. 2. Critical Decision 2: Outsource Components

2. Critical Decision 2: Outsource Components

Questions are now being raised about Boeing’s decision to farm out design and production work—about 70% of the 787’s components are sourced from partners. Tokyo stock exchange-listed battery-maker GS Yuasa, who supplied the Li-ion batteries, is at the centre of the investigations.

3. What Are Boeing’s Losses?

A. It may lose its lead to Airbus: In 2013, the plane-maker said it hopes to deliver 635 to 645 planes. If the issue is not sorted quickly, some airlines could start canceling orders. Boeing has orders for 800 787s, which includes 27 planes for Air India.

B. It may have to take write-offs of up to $5 billion as well as reimburse airlines for their losses. Its factories, as well as those of dozens of suppliers, were ramping up to maximise production. Boeing will have to bear these inventory costs.

B. Component maker Japanese heavy engineering companies including Mitsubishi and Kawasaki have a huge stake—they’ve put up massive foundries to manufacture parts for the 787, like the wing and the fuselage. The project is likely to add significantly to Japan’s own ambitions as a large jet manufacturer. Japanese carriers JAL and ANA are big 787 customers.

First Published: Feb 11, 2013, 06:36

Subscribe Now