CDIL has led the way in semiconductor manufacturing for six decades. What's next

The family-run company introduced silicon semiconductor technology in the country and recently became the first Indian firm to manufacture silicon carbide components

In the 1960s, when India was making its first attempt at manufacturing semiconductor chips, 31-year-old Gurpreet Singh collaborated with California’s Continental Device Corp. to make silicon chips and devices in Punjab’s Faridabad. Months after commencing the business in 1964, the first-generation entrepreneur happened to meet Homi Bhabha, the father of the Indian nuclear program. When Singh told him that they are making silicon semiconductors just outside of Delhi, Bhabha didn"t believe a word of it and said, “Nobody is doing silicon in India, and you can"t be doing it." Only after personally getting it cross-verified did he finally believe it, reminisces Inderdeep, son of the late Gurpreet Singh.

Shortly after, Continental Device India Ltd. (CDIL) became a wholly Indian-owned company and also the first one to manufacture space-grade semiconductor devices for the Indian Space Research Organisation (ISRO). Apart from aerospace, the 59-year-old company manufactures semiconductor devices for sectors including industrial, consumer electronics, defence, and audio. Recently, the company also started supplying semiconductors for solar panels and electric vehicles (EVs).CDIL’s first-ever production lot went for exports because the Indian potential customers in those days were quite sceptical that anybody in India could do silicon. “But eventually, when people saw that it was a reliable product, acceptance in the homeland gradually started picking up," says Inderdeep, president and managing director of CDIL. A few years ago, the company largely exported to countries like the US, UK, China, and South Korea. But now the demand has picked up in the domestic market, and the company supplies 70 percent of their products in India and the rest globally.

The company has designed many devices from scratch. It also ran a wafer fabrication facility in Delhi for over thirty years until 2008, with their own R&D, fab masks, processes, and designs. A semiconductor fab, short for fabrication, is a manufacturing plant in which raw silicon wafers are turned into diodes, transistors and complex integrated circuits (ICs). Later on, CDIL moved to a fabless foundry model and relocated those designs and processes to partner foundries abroad. They still make chips as per the company’s specifications. However, wafer design is not a key focus today. It has shifted to the ATMP (assembly, testing, marking, and packaging) side.

“Our wafers and chip fabrication were quite popular in the Southeast Asian market, and we were selling large amounts of volume to China. Eventually, we stopped our wafer fab because of the transition to the next level of technology. But the fact that we were running our own fab gave us a lot of technical insights into the product. We"ve also been lucky to have the best people work with us," recalls Inderdeep. For instance, Vinod Dham, who is well-known today as the father of the Pentium chip, started his career with CDIL.

In August, the company inaugurated a new surface-mount semiconductor packaging line at their Mohali plant in collaboration with the Government of India’s scheme for promotion of the manufacturing of electronic components and semiconductors (SPECS). With this, adding another first to its credit, CDIL became India’s first silicon carbide (SiC) component manufacturer.

SiC devices are the reason behind the "fast charging" of batteries in EVs and other electronic gadgets. Anything that increases efficiency is there to stay and grow strong, explains Chandranath Dey, India head, operations and BD, L&I, JLL, a global real estate services firm. "The growth of the semiconductor sector in India will provide much-needed fuel to several booming sectors like electronics and consumer goods, automobiles, and the power sector in the forthcoming decade."

Silicon carbide has a significantly wider bandgap compared to traditional semiconductor materials like silicon. This enables the devices to operate at higher temperatures and handle higher breakdown voltages. Consequently, SiC emerges as the optimal choice for the electric vehicle (EV), power management, and solar sectors, as it allows semiconductor components to operate reliably in high temperatures, reducing the need for complex cooling systems.

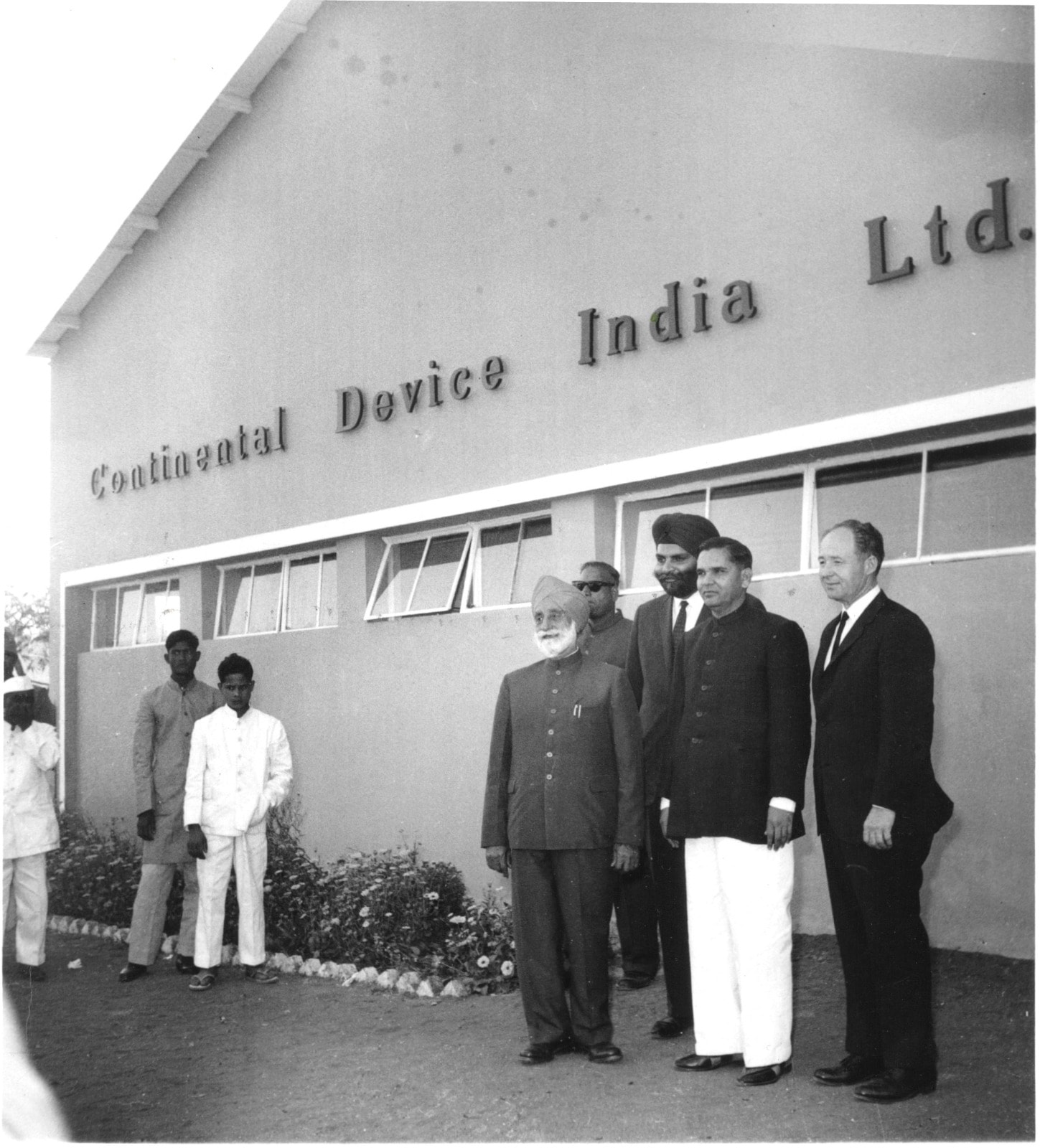

From left: Gurpreet Singh, founder of CDIL, S. Ujjal Singh, first Chairman of CDIL, Commerce Minister Manubhai Shah and Van Winkle, VP and technical director, Continental Device Corporation at the inauguration of CDIL plant in India

CDIL has already initiated pilot production in August with 50 million units and delivered its inaugural batch to customers in both the domestic and international markets. The expansion of assembly lines has increased their total plant capacity to 600 million units annually. At present, it supplies to organisations like Dixon, Luminous, Livgaurd, Vikram Sarabhai Space Centre, Bharat Electronics Limited (BEL), and Hindustan Aeronautics Limited (HAL), among others.

Their semiconductor division also manufactures discrete semiconductors like transistors, diodes, thyristors, MOSFETs, rectifiers, Schottkys, voltage regulators, and transient voltage suppressors, with a focus on high-power devices. The company imports a major chunk of the raw material due to the lack of a semiconductor ecosystem in India. They primarily come from the semiconductor manufacturing hubs in the east.

The veteran company has also signed a MoU with the Semi-Conductor Laboratory (SCL), a research institute in Mohali under the Ministry of Electronics and Information Technology (MeitY), undertaking research and development in the field of semiconductor technology.

The bootstrapped company has been seeing a compound annual growth rate (CAGR) of 25 percent over the last three years, and its revenue stands at approximately Rs250 crore. “We have remained conservative in our expenditure of money and never went into very lavish types of operations. There"s no end to how much you can spend, but you have to be able to survive the down cycles whenever they come, and they will come. Our firm managed to survive the Covid-19 crisis because we didn"t have to worry about servicing debt," says 63-year-old Inderdeep.

An engineer doing wafer inspection at CDIL"s plant in Mohali

About fifteen kilometres away from Chandigarh, CDIL’s plant in Mohali is spread across 16,000 square meters. While giving a tour of one of the oldest semiconductor assembly and packaging plants in India, Prithvideep, the third-generation entrepreneur and general manager of the company, takes us through the process of chip making. From separating the wafer into individual chips (dicing), placing the chips onto a substrate through bonding, to ensuring proper assembly, wire bonding, and packaging of the chips, the whole process is quite complex and needs attention to details. Going forward, the company has plans to deeply focus on making chips for the automotive sector.

“In the past, the semiconductor sector has rarely been viewed as a strategic industry of national importance. Post-Covid-19 pandemic and the global semiconductor shortage, that stance has changed, and the sector’s strategic importance has been imbibed by policymakers in India," says Prithvideep.

It’s a very capital-intensive business, yet the company has managed to stick around for six decades. “CDIL was much ahead of its time, and Gurpreet, the founder, was a very forward-looking entrepreneur. He went through a lot of difficult times to start up the company and get the technology in India, but he eventually managed to do it, and they became the first company to introduce silicon semiconductor technology in India," says Rajoo Goel, secretary general at the Electronic Industries Association of India (ELCINA).

First Published: Oct 09, 2023, 11:50

Subscribe Now