The building blocks for a bio-engineered future

Customised organisms will transform the way we manufacture everything from car seats to cellphones. A group of MIT-trained scientists at $1.4 billion synthetic biology startup Ginkgo Bioworks is brewi

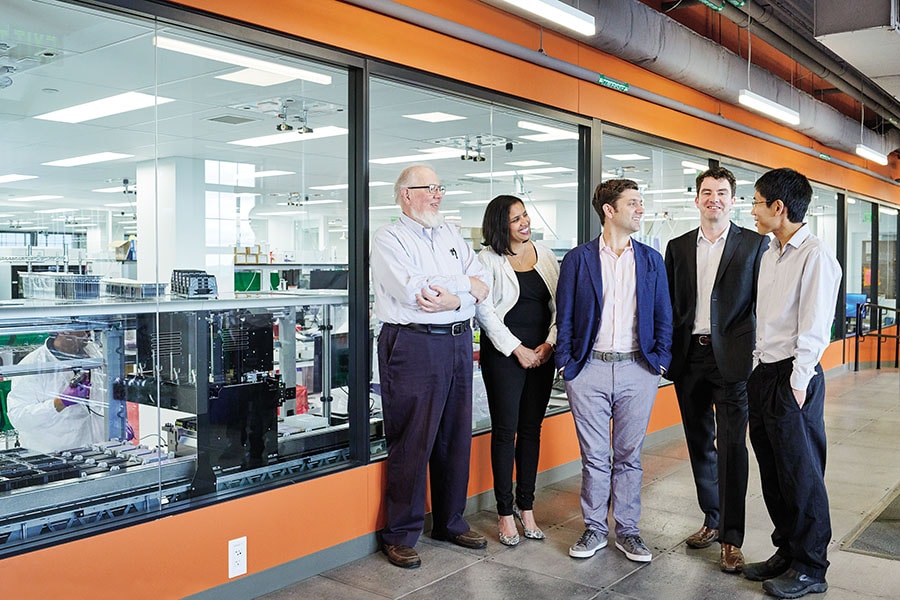

From left: Ginkgo Bioworks co-founders Tom Knight, Reshma Shetty, Jason Kelly, Barry Canton and Austin Che[br] Walk down Drydock Avenue in the old industrial waterfront of Boston and you’ll be reminded that the city remains a significant industrial port. Trucks rattle past the working dry dock. A FedEx shipping container terminal looms to the south while the Coastal Cement Corporation anchors the street. Inside building number 27, Ginkgo Bioworks CEO Jason Kelly and his four co-founders are working on a different industrial vision—one in which biology is at the core. This quintet of modern-day Frankensteins design, modify and manufacture organisms to make existing industrial processes cheaper and entirely new processes possible.

From left: Ginkgo Bioworks co-founders Tom Knight, Reshma Shetty, Jason Kelly, Barry Canton and Austin Che[br] Walk down Drydock Avenue in the old industrial waterfront of Boston and you’ll be reminded that the city remains a significant industrial port. Trucks rattle past the working dry dock. A FedEx shipping container terminal looms to the south while the Coastal Cement Corporation anchors the street. Inside building number 27, Ginkgo Bioworks CEO Jason Kelly and his four co-founders are working on a different industrial vision—one in which biology is at the core. This quintet of modern-day Frankensteins design, modify and manufacture organisms to make existing industrial processes cheaper and entirely new processes possible.

It’s heady stuff. Fertilising corn usually requires spraying acres of farmland with a stew of nasty chemicals. Ginkgo is working on bioengineered, environmentally friendly coatings for corn seeds that will fertilise themselves. Today, most biotech drugs are non-living proteins. Ginkgo is working on creating living creatures, genetically programmed to seek and destroy disease, that would be ingested whole. Fake meat tastes gross. Ginkgo promises to make it taste better.

And that’s just the beginning. Recently Ginkgo recreated the scent of an extinct Hawaiian hibiscus, blurring the line between what’s living and what’s dead. Kelly believes his company will power a science-fiction future where trees naturally grow into the shape of tables, seaweed morphs into car seats and smartphones repair themselves with a few drops of sugar. That’s a long way off, but nearly 11 years after founding Ginkgo, “it’s a little easier to talk about this and not sound like a crazy person”, Kelly says.

These are exciting times for companies like Ginkgo (named after a dinosaur-era tree that’s a living fossil) that work in the emerging field of synthetic biology. Spurred on by technological and economic advances, particularly the plummeting cost of DNA sequencing and the development of a precision gene-editing tool called Crispr, entrepreneurs have been falling over themselves to start companies. Today, more than 600 companies work in the space, according to SynBioBeta, a Pleasant Hill, California-based firm that hosts the industry’s premier conference and maintains a database of synthetic biology startups. And that universe is growing at a rate of 5-10 percent each year, as money pours into these firms, including $3.8 billion last year alone, according to SynBioBeta founder John Cumbers.

These startups run the gamut from sellers of the DNA molecules that are the building blocks of life to high-profile consumer companies. Plant-based-burger startup Beyond Meat went public in May and is now worth nearly $10 billion its synthetic biology competitor Impossible Foods is a venture-backed unicorn that recently began selling Impossible Whoppers to fast-food giant Burger King. Bolt Threads, valued at $700 million, makes bio-based spider silk for use in textiles and skin care. At the other end of the spectrum, Twist Bioscience, the largest seller of synthetic DNA (which counts Ginkgo as its largest customer), went public last year and now has a market cap of nearly $1 billion.

Ginkgo is the leader in organism engineering. “Ginkgo is category defining,” says Cumbers, who first met Kelly when they were PhD students (Cumbers at Brown, Kelly at MIT). “They pretty much created the whole idea of the organism being a product.”

Founded by Kelly, former MIT professor Tom Knight and three other MIT PhDs—Reshma Shetty, Barry Canton and Austin Che—Ginkgo today has gained a toehold in fragrances, agriculture, food, therapeutics and cannabis with some two dozen customers and 50 active engineering projects. Ginkgo doesn’t create any of these products, but by using data analytics and robotics to speed up the process of discovering and making new organisms, Ginkgo will be at their core. Revenue last year reached $40 million, doubling the previous year’s it’s expected to double again this year.

Ginkgo’s bigger bet is a portfolio approach—inspired, in part, by Kelly’s attendance last year at Warren Buffett’s annual Berkshire Hathaway shareholder meeting. Ginkgo now creates and invests in companies, including protein alternative specialist Motif Ingredients, which Ginkgo recently spun off, and Joyn Bio, its agricultural joint venture with Bayer. “That’s how we are scaling the business,” Kelly says. “It’s a Berkshire for biotech.”

An alum of Forbes’s Next Billion-Dollar Startups list, Ginkgo has raised more than $400 million. As of December 2017, it was valued at $1.4 billion. Kelly and his co-founders all still work there and have retained stakes in the company that Forbes estimates at more than $100 million each. Kelly figures he’ll take Ginkgo public eventually. “Biology is programmable, but it doesn’t process information—it builds stuff,” says Kelly, who carries a notebook with an “I (heart) GMOs” sticker on it. “Food, housing, materials, electronics—all will be disrupted by biology.”

*****

Jason Kelly, 38, grew up in Jupiter, Florida, a small beach town near Jupiter Island, the ultra-wealthy barrier island famously home to Tiger Woods. It has since become infamous as the location of the Orchids of Asia massage parlour, where New England Patriots owner Robert Kraft allegedly solicited prostitution. Kelly’s parents, both pharmacists, moved to Jupiter in the 1970s to escape the cold farther north and because the area, with its ageing population, offered more jobs.

By high school, Kelly was excited about the potential of genetic engineering. “There must’ve been at least some seed planted by Jurassic Park,” he says. He did a school project on Herceptin, a genetically engineered antibody used to treat breast cancer, and was wowed by the idea that you could program a cell like a computer.

As an MIT undergrad, Kelly spent two summers in the lab, attempting to move a single gene into the bacteria E coli, which is often used to make drugs. It was slow, frustrating work, and he failed at it. Then he met Drew Endy, a young professor and colleague of Knight’s in synthetic biology. Kelly was so drawn to the idea that the digital code of cells, with its As, Cs, Gs and Ts, could be read and written like a computer program that he joined Endy’s lab as an undergrad. In 2003, he started a PhD in biological engineering at MIT.

The rest of Ginkgo’s student co-founders arrived on campus around the same time. Shetty, 38, had studied venomous cone snails, which use neurotoxins to paralyse their prey, as a teenager in Salt Lake City, but switched to computer science for her bachelor’s degree at University of Utah. Canton, 39, arrived from Ireland after studying mechanical engineering at University College Dublin and developing an interest in, as he puts it, “taming the complexity of biology via engineering know-how”. Che, 39, grew up near Apple’s headquarters, in Cupertino, California, learnt to program at the age of seven and finished a bachelor’s degree in computer science at Stanford before shifting gears.

Knight, 71, a computer expert, had made an unusual midcareer switch. In the 1990s, he’d begun to wonder when Moore’s Law—Intel co-founder Gordon Moore’s observation that the number of transistors on a microchip doubles every two years—would end. The problem, he explains, is that structures eventually become so small that you’re working with silicon at the atomic scale, and placing atoms in the right place with precision requires biochemistry.

In 1997, Knight set up his own microbiology lab in the computer science building. “Some of my colleagues thought I was going to kill them,” Knight says. After all, bioengineers work with bacteria like E coli, which can cause sickness and even death. He didn’t care what others thought. “He unapologetically wanted to program biology, even though all the biologists were like, ‘It’s way too complicated, and all the things you are trying to do are bullshit’,” Kelly says. Ginkgo co-founder and CEO Jason Kelly. “You can’t eat software,” he says. “All the physical stuff will be owned by synthetic biology. That’s trillions of dollars.”

Ginkgo co-founder and CEO Jason Kelly. “You can’t eat software,” he says. “All the physical stuff will be owned by synthetic biology. That’s trillions of dollars.”

Image: Michael Prince for Forbes[br]

MIT’s synthetic biology community was small and closeknit. Shetty and Che worked in Knight’s lab Kelly and Canton worked in Endy’s. The two labs bonded over group lunches, contributing to OpenWetWare, a wiki for sharing biological knowledge, and the International Genetically Engineered Machine (or iGEM) student competition. “Drew and Tom were like magnets, sucking in the bio-nerds,” Kelly says.Kelly broached the idea of starting a company after the four finished their PhDs in 2008. They all wanted to make bioengineering faster, cheaper and easier. “It’s not scientific discoveries that are needed. It’s process engineering,” says Kelly.

With an initial investment of $100,000 from Knight (eventually growing to $140,000), the five started Ginkgo. Their timing was lousy. The financial crisis had pushed the economy into recession. Banks weren’t lending, and venture capitalists weren’t investing. And even if they were, Ginkgo wouldn’t have appealed then. “We don’t look like normal biotech founders,” Kelly says. “No one starts a biotech company out of school and we had no product in mind.”

Instead, they applied for grants to cover living expenses and scrounged for equipment, buying it at auction when other startups failed. They rented a storage locker at UHaul, dragging in liquid-handling robots and lab supplies.

After a few years of trial and error, they had a brainstorm. At MIT, all five had worked on an iGEM competition project that made stinky E coli bacteria smell minty fresh by inserting new genetic material into it. Building off that, they broke into flavours and fragrances. They got their first major deal with French fragrance and botanicals company Robertet and developed a bio-based rose scent. The project was smart because it’s expensive to distill smells from flowers, but most people don’t associate biotech with fragrances. The deal was a coup for Ginkgo. “There was a lot of scepticism about synthetic biology that Jason had to overcome,” says Bryan Johnson, founder of OS Fund and a Ginkgo investor.

*****

The dream of manufacturing stuff from biology goes back a long time. When biotech giant Amgen was founded nearly 40 years ago, its efforts to create a process for producing indigo dye in E coli landed it on the cover of Science magazine. Other companies have attempted to grow spider silk in the lab for decades. In the early 2000s, a wave of synthetic biologists hoped to create fuel from bacteria and yeast, but while replacing hydrocarbons is a good idea for the environment, most biofuels startups failed when the price of oil fell.

“The idea of using biology for industrial purposes has long been a dream,” says Josh Hoffman, CEO of Emeryville, California-based Zymergen, Ginkgo’s closest competitor. “Unless you can get it to work at scale it’s a dream with wonderful appeal, but it’s unlikely to have impact.”

Over the past few years, big economic and technological trends have pushed that dream forward. The cost of DNA synthesis has plummeted from around $4 a base pair (the unit of two nucleobases that form the building blocks of the DNA double helix), when Kelly and his co-founders were students, to just 7 cents a base pair, with even lower prices for bulk orders. The development of Crispr, which allows for precise genome editing, opened up new possibilities. And artificial intelligence and machine learning help synthetic biologists iterate designs for new organisms more quickly.

Against that backdrop, entrepreneurs founded companies with different approaches. Six-year-old Zymergen, for example, now has 750 employees and a partnership with Sumitomo Chemical, a major supplier to consumerelectronics manufacturers. One goal: To put living cells into next-generation display coatings for cellphones to make them scratchproof. CEO Hoffman won’t disclose revenue, but says that its partners will have sold $1 billion worth of products made with Zymergen’s bugs by the end of 2019.

*****

On a recent afternoon in Boston, Canton gives a tour of Ginkgo’s life factories. Inside Bioworks 3, a robot does pipetting, moving fragments of DNA suspended in liquid into a tray with eight rows and 12 columns at a speed beyond human capability. After the cells grow in plastic containers, another robot photographs them and uses that image to accurately pluck the irregularly shaped colonies from the surrounding jelly. The facility is quiet, with relatively few people. Largely, the machines do the work.

The automation allows Ginkgo to test thousands, or even tens of thousands, of designs on each project, Canton says, compared with a traditional lab where a bench scientist might be able to do ten. “We were inspired by what Intel and others do in building their semiconductor facilities,” he says. This winter, Ginkgo opened Bioworks 4, which will work with mammalian cells.

Already, Ginkgo is the largest user of lab-printed DNA in the world—Kelly estimates it uses about 25 percent of the total, or about 50 million base pairs a month—and it recently purchased Gen9, a supplier that specialises in long strands of DNA. It also maintains a massive and growing “codebase” to track and analyse what it has learnt from each project. “You can apply manufacturing theory to cells,” Kelly says. “The more cell programming you do on our platform, the cheaper and easier and faster you do it.”

Kelly believes that scale will allow it to succeed in a variety of unrelated industries. “We all do synthetic biology, but we are a craft brewer and they are Budweiser,” says John Garrett, co-CEO of Glycosyn, which Ginkgo has partnered with to more efficiently produce oligosaccharides, a healthy component of breast milk, in E coli (a boon for mothers who can’t breastfeed but also potentially a treatment for maladies like Crohn’s disease).

The first major deal Kelly struck was with Bayer, the world’s largest seed company since its acquisition of Monsanto. In September 2017, the two created their Joyn Bio joint venture with a $100 million investment, to develop seed coatings that will enable farmers to use less chemical fertiliser. Soybean microbes have an enzyme that lets them take nitrogen out of the air, but corn microbes do not, so Ginkgo is taking genes from the soybean microbe and redesigning them to work in microbes that live on corn. It’s an early-stage big idea—worldwide, farmers spend more than $150 billion a year on fertiliser—that’s at least five years from market, even if all goes well. “The challenge for any big company is how do you realistically go after these moonshots,” says Joyn Bio CEO Mike Miille.

For Ginkgo, Bayer’s interest was a turning point. More deals followed. With Canadian cannabis company Cronos, for example, it is developing lab-grown rare cannabinoids that could be used for appetite suppression and anti-inflammatory creams. If Ginkgo can deliver the strands, it will get stock valued at more than $200 million today. With Cambridge, Massachusetts-based biotech Synlogic, it is working on living, gut-based treatments for liver problems and neurological disorders.

In February, Ginkgo spun out Motif Ingredients which is developing vegan-friendly proteins that can be added to food to replace animal products like meat and cheese, with $90 million in funding from Viking and others. And in May it acquired the genome-mining platform of Warp Drive Bio, a subsidiary of Revolution Medicines, and with it an agreement with pharmaceutical giant Roche to search for a new class of antibiotics, a deal that could be worth $160 million, plus additional royalties if Ginkgo succeeds. Kelly believes he could easily add 50 or 100 more partnerships or investments without maxing out. “Nobody has cracked the puzzle at scale yet,” says Endy, now a professor at Stanford and not affiliated with the company. “Jason, with his business acumen, is testing an experiment with these joint ventures. I think that’s a good way to approach it, and I hope it works. But nobody has done that before.”

Back at Ginkgo’s headquarters, Kelly picks up a copy of Knight’s first cellular computing study, written for the Defense Advanced Research Projects Agency more than two decades ago, and thumbs through it. Stopping at page 14, where a graph shows zero sequenced genomes in 1995 rising to just 10 in 1997, he lets out a loud laugh. “We just acquired a database of 135,000 sequenced genomes.”

Today, he believes, synthetic biology is developing at a similar pace to computing in the mainframe era. As the field develops, he argues, biology will help people live better lives, while moving away from chemical-based processes that lead to climate change and environmental degradation. “Eventually,” he says, “it should be a point of pride. You should want things made with GMOs because they’re made with biology”.

First Published: Sep 04, 2019, 11:50

Subscribe Now