Ishitva Robotic Systems: Mad engineers revolutionising the dump yard

Jitesh Dadlani's technologies at Ishitva Robotic Systems segregate dry waste using automated AI-based machines, sorting 6 tonnes of plastic waste per hour

One of the biggest bottlenecks in the waste management and recycling value chain in India is material recovery and sorting. Jitesh Dadlani spent close to a year with the workforce—mainly women and children—to understand the challenges they faced in sorting out waste. “In India a high volume of waste is generated in Ahmedabad alone, 4,000 metric tonnes are generated per day. How can you pressure humans to sort out so much waste? The challenge for us was how do we handle this kind of waste," recalls Dadlani. As an attempt to solve this issue, he set up Ishitva Robotic Systems in 2018. “People in the industry call us mad engineers coming out of the dump yard," jokes Sandip Singh, the CEO of Ishitva.

Some of the solutions they’ve developed include the Netra Machine Vision system, which provides instructions and insights for material sorting operations on any conveyor belt Suka AI-powered air sorting, which is a plug-and-play high speed mechanical sorting machine for dry waste, and Yuta AI-powered robotic sorting, which is a pick-and-place machine for recyclables with live monitoring and data analysis capabilities. The Ahmedabad-based company sets up a material recovery facility (MRF) for its clients—mostly recycling companies—using all of their solutions.

“We are a tech company, we play the role of being an enabler to the ecosystem, and in order to do that we have created these AI-powered tools," explains Singh. Ishitva charges its clients a one-time cost for setting up operations, and then they don’t look at the day-to-day operations of running the facility. They have four fully operational MRFs across India and, in the next couple of months, another three should be functional as well. In October 2021, the startup raised a Pre-Series A round of over $1 million led by Inflection Point Ventures.

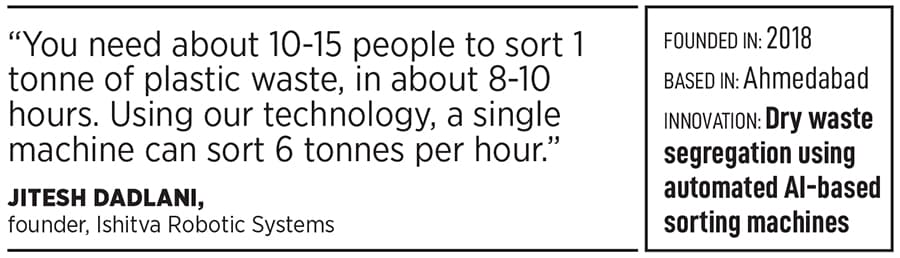

When comparing Ishitva’s innovation to manual labour, Dadlani says, “You need about 10-15 people to sort 1 tonne of plastic waste in about 8-10 hours. However, using our technology, a single machine can sort 6 tonnes of waste per hour." Apart from the time difference, another key factor for recycling, says Singh, is how well sorted is the input that is being fed. “The more refined and sorted the input, the quality of the output will be that much better," he says.

During his research, Dadlani, who worked in the IT sector for close to a decade, saw how poorly labour was being treated. Everyone in India was well aware of this but no one was interested in working in this sector. He says, “They wanted the problem to be solved, but no one wanted to solve the problem." In the next few years, the business hopes to expand to a few more countries as well.

First Published: Feb 23, 2023, 15:54

Subscribe Now