Productivity tip: Stop moving your star workers

Shifting top employees to slower production lines to meet a demand surge might not yield the intended results. Research by Jorge Tamayo reveals how smart staffing can make all the difference

Companies are often eager to land the big fish—a massive order that will boost production and revenue. Yet firms might not understand the costs of serving a large buyer, says Jorge Tamayo, an assistant professor at Harvard Business School.

“We know very little about how the firm needs to adjust internally when they are working with a buyer that is so large, and the [firm] cannot fail [in delivering on the order]," he says.

Examining worker-level productivity data from a large readymade garment manufacturer, with 50 factories and over 100,000 employees in India, Tamayo and his fellow researchers found that when the company received a large order, managers regularly shifted the most talented workers to the slowest production lines in an attempt to keep up with demand.

There is a tension between keeping up productivity and retaining these large clients you can’t afford to lose.

While doing so ensured no single production line fell too far behind, separating the best workers from the managers who kept their lines running smoothly caused overall productivity to drop significantly.

“These moves, driven by larger orders, come at a cost to the company," Tamayo says. “There is a tension between keeping up productivity and retaining these large clients you can’t afford to lose."

The findings, which come as productivity has dipped in recent years in the United States, could have implications for how many industries, including retail and software production, assign workers to projects to maximize productivity, Tamayo says. However, he says, “few companies are paying attention to this."

Tamayo’s paper, “No Line Left Behind: Assortative Matching Inside the Firm," is forthcoming in the Review of Economics and Statistics. He cowrote the research with Achyuta Adhvaryu, a professor at the University of California-San Diego Vittorio Bassi, a professor at the University of Southern California and Anant Nyshadham, a professor at the University of Michigan.

Tamayo and his colleagues accessed hour-by-hour data on more than 20,000 workers assigned to more than 120 production lines in six factories between 2013 and 2016. The team then correlated these figures with order data for more than 100 international buyers, both large and small.

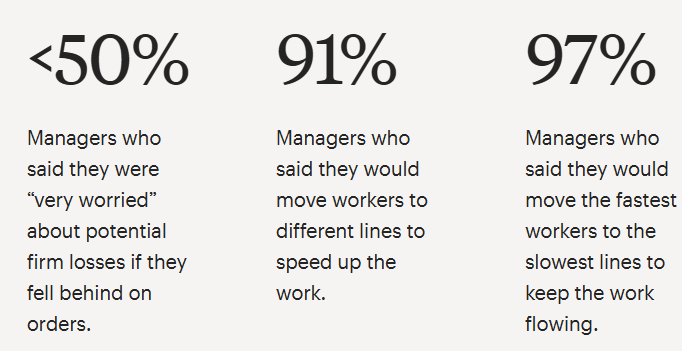

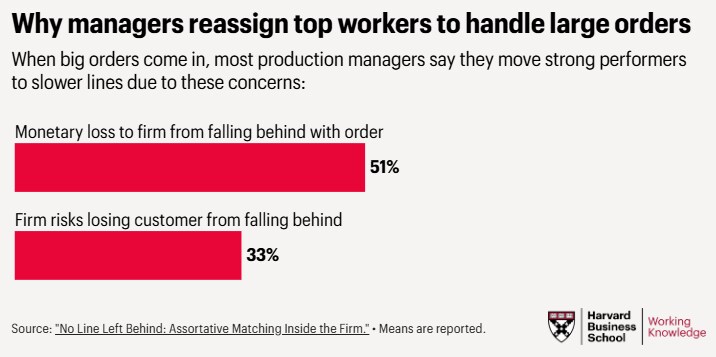

The research team surveyed all 80 managers in the six factories to learn more about how they allocate workers to handle orders. “As soon as you mention the name of a big buyer, they become concerned about how to manage a large order," Tamayo says. The team found:

In fact, the researchers found that the company routinely placed the best workers with the worst managers and vice versa, a phenomenon the team called negative assortative matching. This approach might seem like a good way to keep all lines moving, but it can create an overall lag in production, Tamayo notes. Skilled managers end up spending more time training slower workers, while the better workers pick up the slack for the less skilled managers on other lines.

The drag on the better production lines, they found, outweighs the improvement on the slower lines, so even though the transfer of workers ensured all orders were completed in time, overall productivity decreased between 1 and 4 percent.

“That’s massive!" says Tamayo. “It takes forever to raise productivity by 0.5 percent, so you make a big sacrifice to work with these large buyers."

Merely keeping the best workers aligned with the best managers may not be the answer in all cases, depending on the different orders the company is juggling, Tamayo notes. After all, shifting workers to manage a big order may ultimately pay off in terms of profitability, especially if it leads to future lucrative contracts with a large buyer after the company pulls off a first big order on time, Tamayo says.

The team also found that the need to shift workers diminished over time as the manufacturer established close relationships with buyers, who granted them more leeway when they asked for deadline extensions.

“In the end, this is the cost of building trust," Tamayo says. “At first, you need to show that you will work hard and not fall behind. Once they trust you, you can explain more about your processes."

Beyond thinking strategically about workers, Tamayo says these tactics can help companies stay productive:

By closely tracking clients and their likely demands, companies can organize their production lines better. Rather than shifting workers to scramble on a large order, a firm might consider adding more machines to certain lines to ensure it can keep up with demand.

Train certain employees as generalists who can easily shift from one line to another, whether to help with a large order or fill in for absent employees. When deadline pressures arise, these floaters can be deployed to a slower production line to pick up the slack without needing to transfer faster workers from other lines.

After landing a big client, consider hiring a dedicated crew of workers who can focus solely on the order, freeing other staff to take care of smaller orders. One software developer Tamayo has studied, for example, hires new coders when taking on big projects to keep up with demand without pulling workers away from existing priorities.

First Published: Jun 06, 2025, 17:06

Subscribe Now