Log9 is making India's first EV cells. Can it take on China?

Currently, EV cells are all imported and go into making of the electric scooters, cars, buses and commercial transport vehicles

The atmosphere was one of bonhomie at Log9 Materials’s campus in Bengaluru, one hot day in April. In fact, only the previous week, the Met department had recorded 36.5°C at the international airport in India’s tech capital, making this one of the hottest Aprils since we started keeping records.

No one seemed to mind the heat, sitting outdoors and semi-outdoors around a makeshift stage, on which Rajan Anandan, managing director at Sequoia Capital, invited an expert, Michale Liedtke, chief commercial officer at Zeta Energy Corporation, to explain the real event, which was being beamed on a large screen behind him.

That event was the rolling out of India’s first privately manufactured lithium-ion cell, happening inside, in a controlled-environment facility. Along with the founders of Log9, two stalwarts of India’s tech leadership, K VijayRaghavan, former principal scientific advisor to the Government of India, and K Sivan, former chairman of Isro, were gathered around a machine that completed the final steps to roll out India’s first privately made commercial lithium-ion cell.

Outside, on the tables for the journalists and guests, alongside bottled water, there were mockups of the cells. They showed that Log9 was making two versions of the cells.

Currently, EV cells are all imported and go into making the batteries for India’s growing number of electric scooters, cars, buses and commercial transport vehicles.

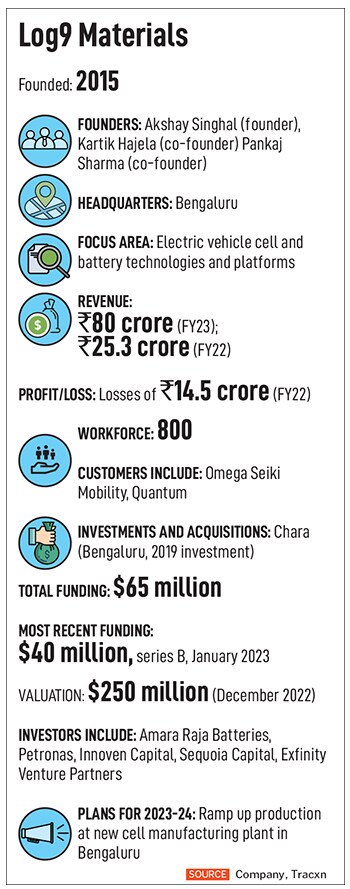

Later, the Davids, nay, the nano-Davids dreaming of India holding its own against the Goliath of cell manufacturing, China, Akshay Singhal, Kartik Hajela and Panjak Sharma, took turns to explain how their cells—one rated 3.2V 50Ah and the other 2.3V 50Ah—were better than what’s available in the market today.

One is a lithium ferro phosphate cell and the other is a lithium titanium oxide cell. The cells are also being turned out to “tropical" conditions, according to Log9, whose marketers have also coined the term TiB, for “tropicalised ion battery."

The cells were 14 percent and 33 percent more “energy dense" respectively, Hajela explained. Meaning, basically, they pack more energy per unit amount of whatever’s inside the cylindrical cells.

The engineers have innovated in areas including something called “tab-less technology" (an India first), an advanced electrolyte interface that reduces what’s called “ohmic resistance", an “advanced fast formation protocol", vital to producing large numbers of cells, and laser welding techniques, explained Hajela, along with Robin George, vice president at Log9, and the energy storage specialist who led the R&D effort to boost the energy density of the cells. In an EV battery, “this has implications for not just increasing range, but also for using less material for the range," Hajela said.

George and his team have also introduced innovations aimed at keeping the cells within an acceptable temperature range so that they can be fast-charged safely.

Log9’s cell factory is commercial, but a small one for now, capable of about 50MWh of annual cell production capacity—roughly enough for making battery packs for about 1,500 two-wheelers every month. Its founders have plans to raise capacity to Gigawatt-scale in the next three to five years, investing about $20 million in the plant, and Singhal expects to keep ramping up the infrastructure, he has previously told Forbes India.

In comparison, China has about 250 GWh (gigawatt hours) of annual capacity, which is about three quarters of the global capacity. And China has plans to raise its capacity to nearly 2TWh (terawatt hours) by 2025-26.

For anyone who still had doubts about the importance of Log9’s small first step, VijayRaghavan, who spoke briefly on stage that day, pointed out that “at the core of everything in deep tech are cell and battery technologies". He outlined the big picture: India is attempting to bring technology to the masses—from health care and agriculture to surfacing the benefits of deep ocean research.

All of this require “non-grid deployment of electricity", which means that unless India supports companies such as Log9 to ramp up their capacities, we will be cripplingly switching our fossil fuel import dependence to imports of cells and batteries.

K Sivan was ecstatic on stage: “I want to see Log9 become another Isro," he said.

India’s space scientists are also helping the country’s fledgling private cell manufacturing effort. In 2018, Isro offered to transfer its lithium-ion cell technology to startups and industry partners interested in establishing private production facilities—for the modest sum of just `1 crore. Isro also offered to help these partners familiarise themselves with the tech at its Vikram Sarabhai Space Centre. More than 140 companies signed up.

In Log9’s case, “we built the cell technologies on our own, from ground up," Sharma said.

One of the biggest challenges in the way of India becoming self-reliant in electric vehicles (EV) is the import of lithium-ion cells that are used to make up the batteries that go into EVs as well as static energy storage solutions.

Singhal, Hajela and Sharma see Log9 as a deep-tech, nanotechnology company, developing cell and battery technologies ground-up in India, specific to tropical world conditions. Singhal and Hajela started the company in 2015 out of IIT-Roorkee. Sharma, the third co-founder, is a serial entrepreneur, and previously founder and CEO of a biotech startup. They lead a team of 800 engineers now.

Backed by investors including Amara Raja Batteries, Exfinity Ventures and Sequoia Capital, Log9 has commercialised fast-charging and longer-lasting battery packs for commercial vehicle applications they also have a line of products for residential and office spaces that can be integrated with rooftop solar.

Around the world, there is a surge in government initiatives aimed at local cell manufacturing to break the Chinese dominance and become more self-reliant. From Europe and the US to India, governments have announced policies offering incentives for local manufacturing.

The metals that go into cells, such as lithium—even though it makes up a very small proportion of the cell—are geostrategic commodities. More recently, there has been much excitement over a large find in Kashmir, but it’s going to be at least a decade before India will have actually commercially extracted anything.

India imported about $1.2 billion of lithium-ion batteries in the fiscal year that ended March 31, 2019—tripling from the previous fiscal—and an additional $929 million in the subsequent eight months, The Economic Times reported in February 2021, citing Harsh Vardhan, Union minister for science and technology.

According to an independent study by the Centre for Energy Finance, the EV market in India will be a $206 billion opportunity by 2030 if India maintains steady progress to meet its ambitious 2030 target. This would require a cumulative investment of over $180 billion in vehicle production and charging infrastructure.

By 2030, demand for batteries in India will be 158GWh as commercial electric cars and two-wheelers become common. Today, it’s around 2GWh. And that 150GWh will likely be at the lower end of the demand for mobility alone, and overall demand could be much more if one includes the static energy storage market, Singhal had earlier told Forbes India.

India Energy Storage Alliance projects that the Indian EV market will have a compound annual growth rate (CAGR) of 36 percent till 2026. The EV battery market is also projected to have a CAGR of 30 percent during the same period.

In addition to manufacturing, Log9 has also invested in, and partnered with a cell-recycling startup, which the company hasn’t named. Battery and battery cell recycling will be a critical component of the overall push towards self-reliance in EV technologies in India.

Other ventures such as Lohum Cleantech in Delhi, for example, are also establishing the recycling ecosystem in India. Log9 is also working on developing aluminium fuel cells, which could eventually be used for long-haul applications. And while Log9 is first off the block, other cell technology platform startups are emerging—such as e-Trnl Energy, also in Bengaluru, looking to reimagine cell design and manufacturability to make them cheaper, faster and safer.

That day at Log9, the event was called ‘Day Zero’. And while the happy atmosphere dispelled the heat, the high temperature was also a reminder of one critical problem that companies like Log9 could have an impact on, if they succeeded at scale—climate change.

First Published: May 09, 2023, 12:32

Subscribe Now