Bio doesn't always mean better, need to validate sustainability claims

Katrin Ley of Fashion for Good talks about the many complexities of creating eco-friendly materials

Katrin Ley

Katrin Ley

Image:Alina Krasieva[br]The search for sustainable alternatives to existing materials in the fashion industry—one of the world’s most polluting sectors—has increased in the last few years, as brands consider their environmental and social impacts and consumers raise ethical concerns. This has given rise to an excitement around ‘bio-materials’ as alternatives to existing materials used in the fashion industry.

Bio-materials, however, remain an ill-defined category, with words such as bio-fabricated, bio-synthetic or bio-based used in relation to innovations in this space. Fashion for Good, a global platform for sustainable fashion innovations, teamed up with Biofabricate, a platform for bio-material innovators and brands, to conduct interviews of more than 30 global material innovators and consumer brands, and has compiled the learnings to help the fashion industry understand these various terms and innovations.

Their report, titled ‘Understanding bio-material innovations: A primer for the fashion industry’ was released on December 7, and provides definitions representing key material technologies being practiced today, a model for how to understand these different technologies, key steps in the production of such materials, and potential inputs and outputs to help identify impact hotspots.

In an interview with Forbes India, Katrin Ley, managing director of Fashion for Good, explains the innovations taking place to create materials with reduced environmental and social impact, and the road to making these materials commercially viable.

Q. What makes a fabric truly sustainable?

All materials have different environmental and social impacts associated with them. Conventional cotton production accounts for one-sixth of all pesticides used globally, impacting farmers and local communities with harmful chemicals. Polyester, one of the most commonly used fabrics, can take over 200 years to decompose. What’s important is that each brand is aware of their most commonly used materials and works towards implementing better supply chain and manufacturing processes associated with these materials. That could be transitioning towards BCI (Better Cotton Initiative) or organic cotton or using recycled polyester. There are often more sustainable options for conventional fibres and it’s about having a strategy and/or commitments to move towards these better materials.

Q. What are the different kinds of bio-based materials?

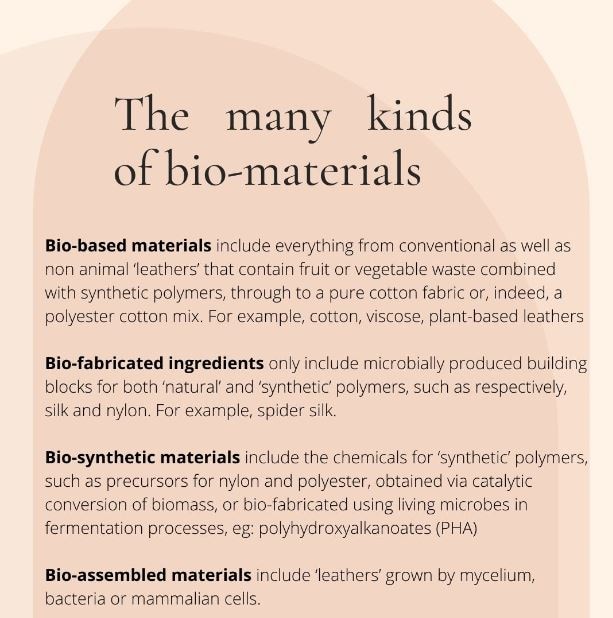

Bio-based materials include everything from conventional and non-animal ‘leathers’ that contain fruit or vegetable waste combined with synthetic polymers, through to a pure cotton fabric or indeed a polyester-cotton mix. All bio-materials are bio-based, but the bio content can vary radically, from less than 10 percent to 100 percent. Most bio-synthetic, bio-fabricated, or bio-assembled materials can also be described as bio-based.

Some bio-synthetic materials are bio-based but not bio-fabricated, while some contain bio-fabricated ingredients that use living organisms—such as microbes, rather than plants or animals—in their production. All bio-assembled materials use living organism to grow into the actual macro material structure. (see box) Q. Can natural fibres really be sustainable?

Q. Can natural fibres really be sustainable?

All fibres have an environmental impact, from raw material extraction to end-of-use. The impact of these different materials varies depending on the hotspots you are looking at, for example carbon emissions, chemicals, water, end-of-use, etc. Synthetic fibres, for example, are produced using non-renewable, virgin resources and also shed micro-fibres during use. On the other hand, a lot of natural fibres require land to grow the materials.

Bio-materials cover a wide range of different materials. It is crucial to be able to evaluate the environmental and social impact of new innovations to understand that overall these new materials have a lower footprint than those they are looking to replace. Data plays a key role in this. Bio doesn"t always mean better, and we do need to be able to validate sustainability claims. It’s important for innovators, brands and manufacturers alike to have an understanding of how these new innovations fit into the existing ecosystem.

Q. Are bio-materials the sustainable alternative to existing fibres used in the fashion industry?

Bio-fabricated or bio-assesmbled materials can be used as replacements for existing materials such as silk, nylon or leather. Companies such as AMSilk, Bolt Threads, Ecovative, Modern Meadow, MycoWorks, and Spiber represent a new generation of material innovations that combine expertise in organism design and engineering, fermentation and materials science. Such a coming together of disciplines would previously only have been possible by the likes of a DuPont, DSM, BASF etc.

It is still the very beginning of a material revolution that will unfold over the coming decades. The promise of these technologies is that designed biology allows access to all the benefits of nature"s performance, aesthetics, comfort and beyond, but without the same environmental footprint. Currently, the demand for new bio-material innovations massively outstrips supply, especially in the newer bio-fabricated sector.

Q. Do you foresee these new materials completely replacing existing fibres in the future?

There is a common misconception that these radical new material innovations are ‘just around the corner’. Contrary to the sense one might get from media reports, only one or two bio-fabricated textile products are in the market in 2020.

One example is German company AMSilk’s bio-fabricated watch-strap with luxury brand Omega (launched in 2018), while in 2019 Japanese company Spiber launched a limited edition series of jackets in collaboration with The North Face and couture collections with designer Yuima Nakazato and T-shirts with Sacai.

It’s unlikely that these new materials will completely displace existing materials. Alongside innovations in this space we still need innovations to continue to develop in the wider materials space, for example chemical recycling or utilising waste feedstocks to make natural fibres.

Q. What are the challenges of making sustainable fabrics commercially viable?

While all entrepreneurs seek to get to market fast, the reality of scaling these complex technologies is that they take time, and many ‘bumps’ are likely to be encountered along the way. From engineering cells to produce proteins, scaling organisms from petri dishes to large fermentation facilities, until they are able to spin them into fibres or into materials—each process requires specialised expertise and equipment. This is why some companies choose to partner strategically. Even so, scaling the technology can take months to years.

The challenge of transitioning a new technology from pilot or demo scale, to being able to supply consistent quality and volume for running on a commercial manufacturing line is often referred to as the ‘valley of death’. Factors affecting scalability also include access to sufficient capital, affordability, reliability, supportability and so on. None of the bio-fabricated material innovators today have yet bridged that gap, though a few are about to attempt to do so.

Both Spiber and AMSilk were founded over a decade ago—an indication of the true length of time it takes to bring a bio-fabricated material to market. Neither company is producing commercial volumes at a global scale yet, though Spiber’s first commercial scale plant is due to come online in 2021, and AMSilk are on track to scale production for a major brand partner launch in 2021. Bolt Threads plan to launch products made of Mylo with their consortium of brand partners in 2021, while MycoWorks, having debuted Reishi in February 2020, are also set to announce brand partners this year.

Q. Which are the countries and companies most actively involved in promoting the making and use of sustainable fabrics?

We see innovations coming from across the globe. It"s important for all stakeholders throughout the supply chain to be involved in the innovation development process.

To help move faster in scaling innovations, stakeholders in the industry, such as brands, manufacturers and investors, are looking to consortia. These types of engagement models were discussed during several interviews, with a few startups actively seeking to put these in place. Some in the field have already announced powerful partnerships—for example, the consortium formed by startup Bolt Threads, with Adidas, Kering, Lululemon and Stella McCartney, to launch its Mylo ‘unleather’ in 2021.

First Published: Dec 07, 2020, 16:16

Subscribe Now